July 2024

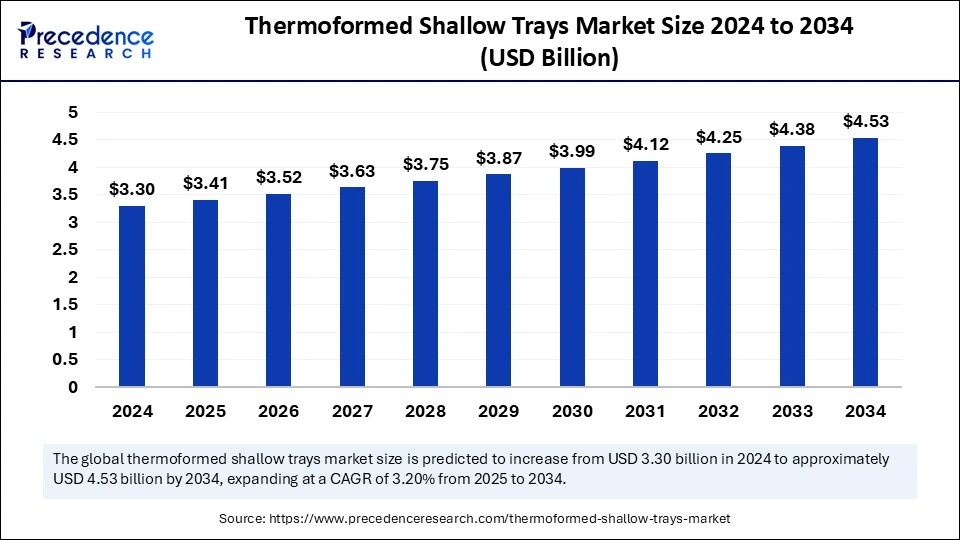

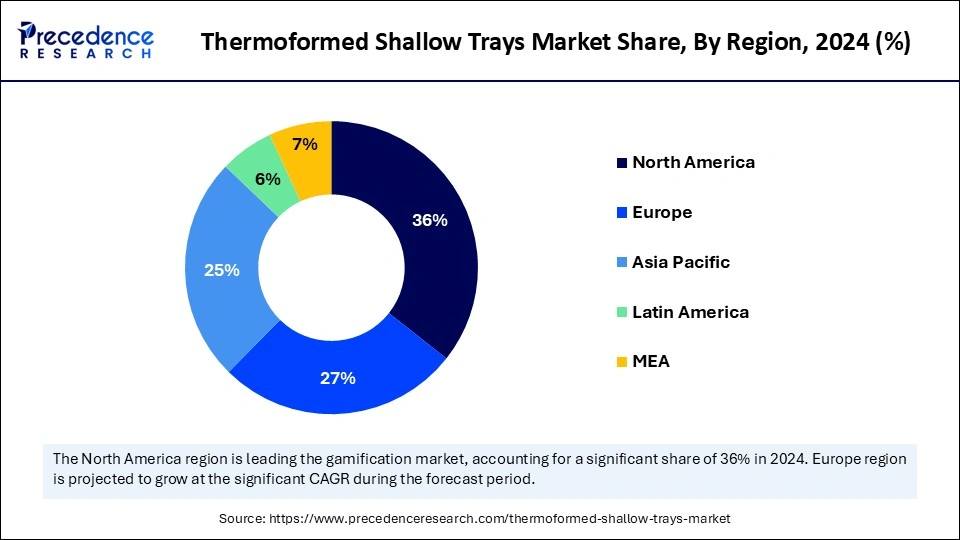

The global thermoformed shallow trays market size is calculated at USD 3.41 billion in 2025 and is forecasted to reach around USD 4.53 billion by 2034, accelerating at a CAGR of 3.20% from 2025 to 2034. The North America market size surpassed USD 1.19 billion in 2024 and is expanding at a CAGR of 3.32% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global thermoformed shallow trays market size was estimated at USD 3.30 billion in 2024 and is predicted to increase from USD 3.41 billion in 2025 to approximately USD 4.53 billion by 2034, expanding at a CAGR of 3.20% from 2025 to 2034. The market is driven by growing business needs for budget-friendly, lightweight packaging solutions that serve industries like food, retail, and electronics.

Artificial intelligence systems penetrate the thermoformed shallow trays market through strategic improvements in manufacturing processes, product design methods, and distribution operations. Manufacturers utilize AI-powered systems to optimize their thermoforming operations and achieve better efficiency while cutting down on waste. The real-time production data analysis using machine learning algorithms enables manufacturers to spot and handle material quality issues, thus reducing product defects for maximized output quantities. Artificial intelligence is creating advancements in design concepts that enable the creation of advanced customized packaging solutions.

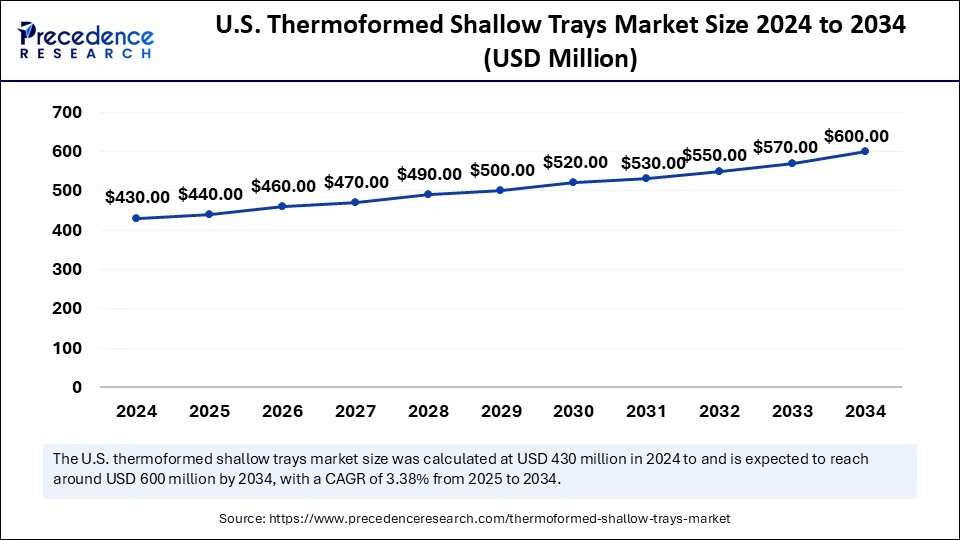

The U.S. thermoformed shallow trays market size was exhibited at USD 430 million in 2024 and is projected to be worth around USD 600 million by 2034, growing at a CAGR of 3.38% from 2025 to 2034.

North America Thermoformed Shallow Trays Market Trends

North America held the dominating share of the thermoformed shallow trays market in 2024 due to the robust manufacturing infrastructure and rising demand throughout the region. The awareness of sustainable materials for thermoformed trays has become more widespread throughout North American businesses because of the growing consumer demand for environmentally friendly packaging materials. The strong manufacturing facilities in North America produce high-quality trays that serve industries such as electronics, cosmetics, and pharmaceuticals.

The U.S. stands as a leading manufacturing hub worldwide and maintains a well-developed production system. The fast-growing food and beverage sector of the country drives the market because manufacturers utilize thermoformed shallow trays extensively to package ready-to-eat meals and packaged foods.

Asia Pacific Thermoformed Shallow Trays Market Trends

Asia Pacific is expected to witness the fastest rate of growth during the predicted timeframe. Industrialization and urbanization across China and India create a growing need for efficient packaging solutions that are also cost-effective. Competing food and beverage producers continue to adopt shallow thermoformed trays because of rising consumer demand for ready-to-eat convenient containers. The adoption of sustainable materials during thermoforming operations through manufacturers continues to advance thermoformed shallow trays as popular sustainable packaging choices.

The rapid industrial development and urbanization in China created substantial packaging requirements in the food and beverage industries, pharmaceuticals, and personal care domains. Manufacturers in China are adopting eco-friendly materials for packaging due to growing sustainability concerns, government regulations, and increasing consumer environmental awareness, which in turn makes thermoformed trays more appealing.

Europe Thermoformed Shallow Trays Market Trends

Europe is observed to grow at a considerable growth rate in the upcoming period. The market expansion occurs because industries require efficient, sustainable packaging solutions, and the food and beverage sector demonstrates significant growth. The increasing environmental awareness among consumers has compelled manufacturers to adopt recyclable and biodegradable thermoformed trays because consumers prefer environmentally friendly packaging materials.

The strong regulatory programs that promote sustainable packaging solutions. The European thermoformed shallow trays market will experience substantial growth due to rising consumer demand for convenience products and environmental considerations.

Lightweight, durable thermoformed shallow trays serve multiple purposes in various industries through their role as packaging containers, storage units, and display platforms. Production of these trays takes place through thermoforming by using either plastic or paper-based laminates. The food and beverage industry utilizes thermoformed shallow trays for product protection throughout transportation because these trays help prevent damage to contents. Thermoformed shallow trays possess essential status in the packaging industry due to their efficient manufacturing process and broad application areas.

The market will expand due to industries emphasizing product defense and quality, which requires thermoformed shallow trays. The e-commerce market expansion, coupled with rising consumer online buying activities, has made secure and effective packaging solutions essential for shipping protection purposes. The market anticipates broad adoption of adaptable yet inexpensive shallow trays among various industries because of their flexible nature.

| Report Coverage | Details |

| Market Size by 2034 | USD 4.53 Billion |

| Market Size in 2025 | USD 3.41 Billion |

| Market Size in 2024 | USD 3.30 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 3.20% |

| Dominating Region | North America |

| Fastest Growing Region | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material, Application and Regions. |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Rising demand for convenient packaging

The thermoformed shallow trays market receives significant growth from consumer preferences toward convenient solutions. People adopt active lifestyles where pre-packaged items, ready-to-eat meals, and grab-and-go products experience increased consumer demand. The increasing need for convenient packaging solutions is addressed through thermoformed shallow trays because they offer an efficient packaging design. Thermoformed packages have become popular for perishable item packaging because they preserve food freshness and offer protective properties.

The lightweight functionality helps maximize storage efficiency while permitting easy stacking. Thus, companies can reduce their package, distribution, and storage costs. Sustainable material alternatives provided by thermoformed shallow trays work to reduce waste within the packaging solution. Market expansion of sustainable packaging innovations has been driving up the demand for thermoformed shallow trays, resulting in increased market growth.

Financial setbacks

Restricted funding makes thermoforming machine acquisition and installation costs a major financial barrier for businesses. The purchase expenses and operational costs from machinery produce major financial difficulties for businesses. This maintenance cost accumulation generates a rising financial problem for market businesses. Thermoforming machines need skilled workers for operation and management, thus driving up total operational expenses.

Smaller businesses face problems when hiring specialized workers because they lack a recruitment budget. The thermal shallow tray market presents entry barriers for new and existing businesses because setup fees remain expensive while operational costs remain ongoing.

Increasing adoption of sustainable packaging

The expanding awareness about environmental issues has led consumers to select goods with green packaging materials. The market requires recyclable, biodegradable, or compostable materials in thermoformed shallow trays for a sustainable solution. The trays exhibit sustainability advantages that make them preferred choices instead of cardboard and plastic wrapping because they decrease environmental waste impacts. These low-packaging designs serve all the functions of typical packaging materials and maintain comfort factors while supporting sustainability practices.

Businesses across different sectors must address rising concerns about environmental stewardship because thermoformed shallow trays have emerged as the preferred packaging solution for food, electronics, pharmaceuticals, and cosmetics items. The market for eco-friendly thermoformed shallow trays demonstrates high potential for growth because sustainability has become a consumer priority and a business requirement.

The plastic segment contributed the largest share of the thermoformed shallow trays market in 2024. Shallow plastic trays undergo thermoforming when a plastic sheet undergoes heating, followed by mold shaping during its pliable state. The plastic materials for thermoforming include Polyethylene Terephthalate (PET), Polyvinyl Chloride (PVC), Polypropylene (PP), Polyethylene (PE), and Polystyrene (PS). PET packaging works excellently as food packaging because it functions as a powerful moisture and vapor barrier that protects freshness and product integrity.

PVC stands as an economical material that works effectively in food industries, healthcare, and consumer product applications. The superior chemical resistance and long-lasting characteristics of packaging materials help PP, and PE lead both the electronics industry dominance as well as the packaging of sensitive goods. The lightweight thermoformed plastic trays provide better transport logistics while improving product display during shipment.

The paper-based laminated segment is expected to grow considerably due to the rising demand for sustainable packaging solutions. The paper-based materials with a protective coating create these trays that become molded into lightweight, three-dimensional containers. The sustainable properties of paper-based laminates include biodegradability, recyclability, and compostability, thus providing better environmental advantages over conventional plastic packaging.

The food packaging segment accounted for the largest share of the thermoformed shallow trays market. The thermoformed shallow trays serve as outstanding food packaging alternatives because they offer convenient portability as well as improved capacity for storage. These trays receive marketing details and essential product information by using their printing technology to inform customers better.

A rise in thermoformed shallow tray demand stems from both the packaged food industry growth and the expanding food sector market. Businesses continue to demand thermoformed shallow trays because their market growth occurs from two concurrent trends including consumer preferences for convenience food and industrial demands for protective customized packaging solutions.

The pharmaceutical segment is anticipated to witness significant growth over the studied period. The market requires shallow trays made through thermoforming because they protect medications while keeping their integrity intact. Increased healthcare requirements for single-use sterile packaging drive the healthcare market to adopt thermoformed trays in medical facilities and diagnostic test areas.

Biomedical technology advancements have made specialized packaging mandatory because it must provide essential features such as tamper-proof design, visibility tracking, and user-friendly operation. The pharmaceutical sector of the markets will continue to grow because of safety requirements and compliance standards.

By Material

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

July 2024

July 2024