October 2024

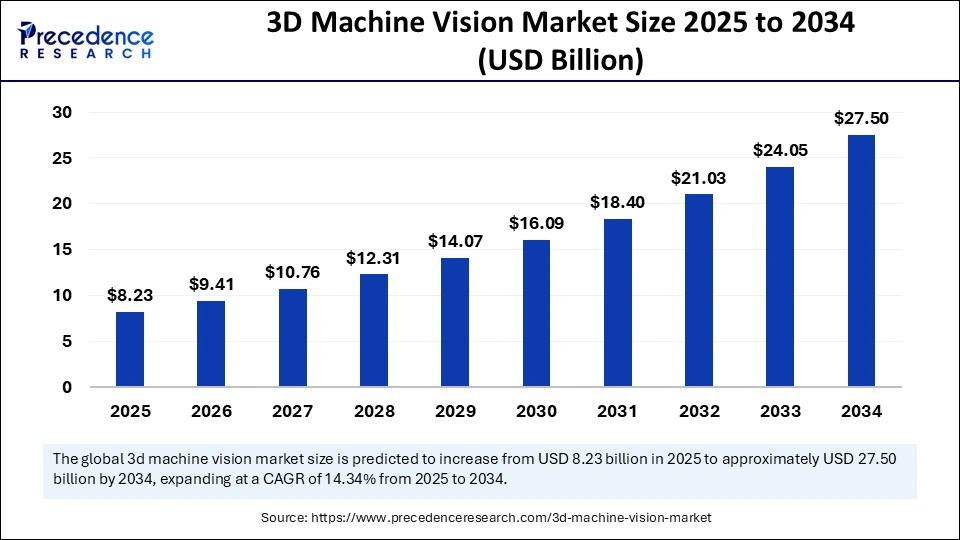

The global 3D machine vision market size is calculated at USD 8.23 billion in 2025 and is forecasted to reach around USD 27.5 billion by 2034, accelerating at a CAGR of 14.34% from 2025 to 2034. Asia Pacific market size surpassed USD 3.02 billion in 2024 and is expanding at a CAGR of 14.49% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global 3D machine vision market size accounted for USD 7.2 billion in 2024 and is predicted to increase from USD 8.23 billion in 2025 to approximately USD 27.5 billion by 2034, expanding at a CAGR of 14.34% from 2025 to 2034. Increasing demand for automation across different industrial sectors is the key factor driving market growth. Also, the ongoing adoption of innovative technologies in 3D machine vision, coupled with the rising demand for precise inspection, can fuel market growth further.

Artificial Intelligence plays a transformative role in the market by improving capabilities such as precise measurements, automated defect detection, and integration with robotics, which leads to increased accuracy and efficiency in different industries. Furthermore, AI-driven 3D vision systems can easily identify and classify defects, minimizing manual inspection efforts and enhancing overall product quality. AI can be utilized to process vast datasets generated by these systems.

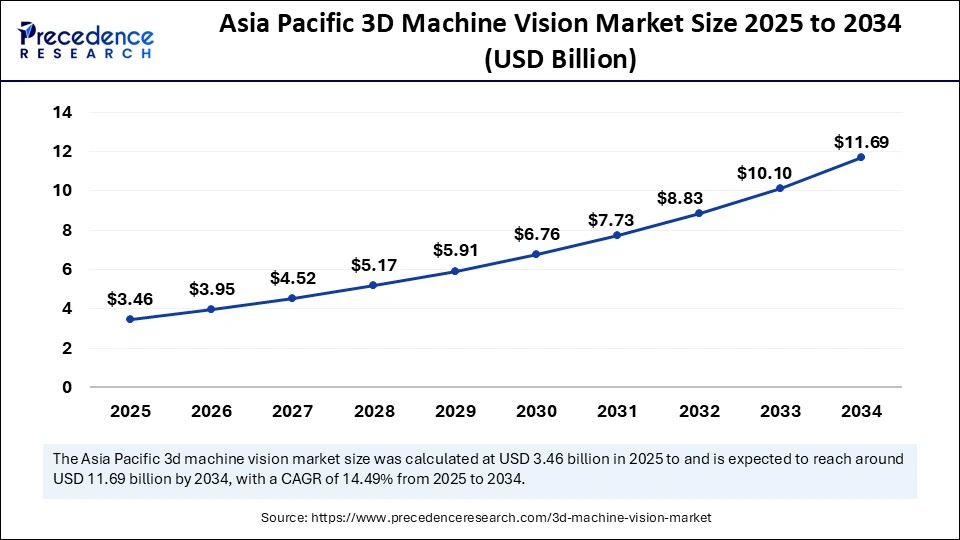

Asia Pacific 3D machine vision market size was exhibited at USD 3.02 billion in 2024 and is projected to be worth around USD 11.69 billion by 2034, growing at a CAGR of 14.49% from 2025 to 2034.

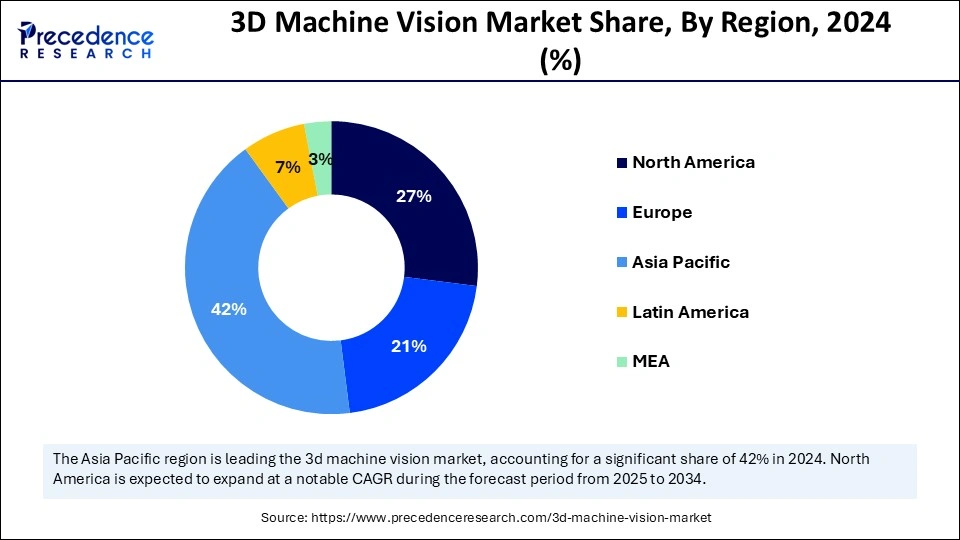

Asia Pacific dominated the 3D machine vision market in 2024. The dominance of the region can be attributed to the growing adoption of automation across different sectors like automotive and pharmaceuticals, coupled with the rapid industrialization in emerging economies. Moreover, countries like China and Japan are heavily investing in technological and manufacturing development. Also, government initiatives focusing on improving production capabilities are impacting positive regional growth further.

In Asia Pacific, China led the 3D machine vision market owing to the strong presence of major market players in the country. A large number of organizations are rapidly introducing strategic initiatives such as mergers, distribution agreements, and acquisitions, which in turn result in a surge in R&D expenditure in the market.

North America is expected to grow at the fastest rate over the projected period. The growth of the 3D machine vision market can be credited to the region's increasing emphasis on innovative manufacturing technologies and industrial automation. Furthermore, the region is rapidly prioritizing operational efficiency and quality control, which leads to a growing need for technology that combines smoothly with current systems and decreases product defects.

In North America, the U.S. dominated the 3D machine vision market. The dominance of the region can be driven by the ongoing expansion of the automotive sector in the country, along with the country's growing focus on advanced manufacturing technologies. The U.S. is a world leader in using automation, which drives the demand for efficient and precise manufacturing processes.

The 3D machine vision market encompasses the technology that enables machines to understand and perceive the 3D structure of objects in their surroundings. This is done by capturing images from many angles, using sensors and cameras, and then utilizing software to create a 3D model. This ability of 3D machines enables a more detailed understanding of an object's size, shape, and spatial orientation, which makes it valuable in applications like logistics, manufacturing, and quality control.

| Report Coverage | Details |

| Market Size by 2034 | USD 27.5 Billion |

| Market Size in 2025 | USD 8.23 Billion |

| Market Size in 2024 | USD 7.2 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 14.34% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Offering, Product, Application, End Use and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Growing adoption of Industry 4.0 technologies

The increase in emphasis on Industry 4.0 by major players is the key factor driving the growth of the market. Machine vision is the most important component of automation technologies in Industry 4.0. Combining 3D machine vision in factories enables more flexible and efficient production. In addition, quality control can be substantially enhanced by incorporating 3D machine vision to detect faults in the products.

In April 2024, Cognex Corporation, the leader in industrial machine vision, released the Insight® L38 3D Vision System, which combines AI, 2D, and 3D vision technologies to solve a range of inspection and measurement applications.

Complexity of integration

3D imaging systems are generally hard to maintain, difficult to install, and challenging to run without skilled personnel. Cost-sensitive customers may prefer 2D vision systems over 3D imaging as they are less expensive than 3D systems. However, many end-user requirements create substantial hurdles for companies, particularly the manufacturing industry, which emphasizes product customization, hindering market expansion further.

Rising need for automated quality inspection technology

The surge in demand for automation and quality inspection across various end-user industries will likely create future market opportunities in the market. Also, the demand for vision-guided robotic systems in food and beverage, pharmaceutical and chemical, automotive, and packaging is impacting market growth positively. Furthermore, major pharmaceutical companies are creating innovative anti-obesity drugs for weight management and loss, which can be inspected by 3D machine vision.

The hardware segment dominated the 3D machine vision market in 2024. The dominance of the segment can be attributed to the growing demand for innovative sensor technologies and imaging systems. Hardware components like lasers, cameras, and lighting systems play an important role in offering precise and high-resolution data in machine vision systems. Additionally, the forward push towards automation and growing demand for high-quality inspections in manufacturing can drive segment growth shortly.

The software segment is expected to grow at the fastest rate over the forecast period. The growth of the segment can be credited to the increasing emphasis on the Internet of Things (IoT) and smart manufacturing that supports the growth of software offerings. Companies need adaptable solutions that smoothly combine different hardware systems. Also, deep learning in technology is contributing to the segments' overall growth.

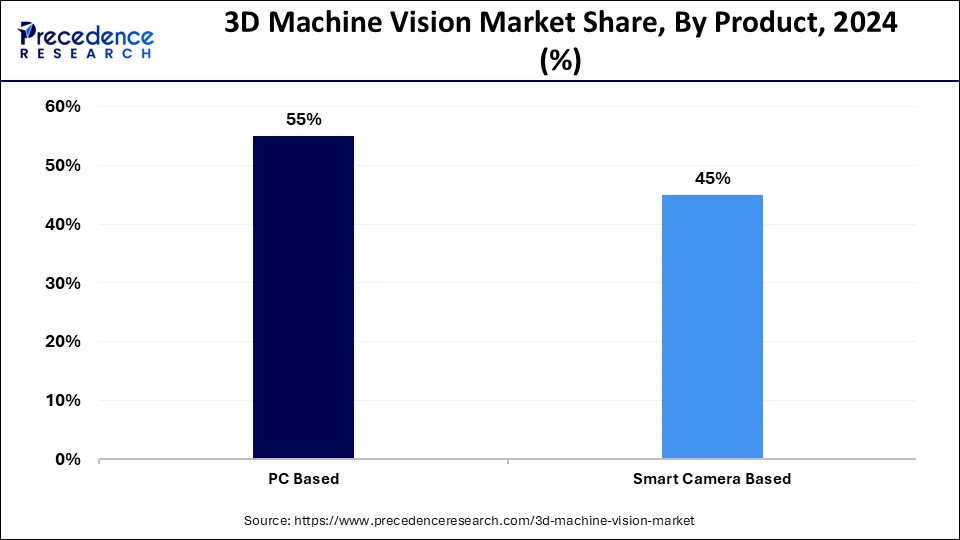

The PC-based products segment held the largest 3D machine vision market share in 2024. The dominance of the segment can be linked to the rising digitalization of daily work and life, along with the surge in e-commerce, gaming, and digital services. The increasing shift towards online education and remote work has propelled the demand for high-performance and reliable PCs, especially tablets and laptops.

The smart-camera-based segment is anticipated to grow at the fastest rate over the forecast period. The growth of the segment can be driven by a surge in the use of these cameras for high-resolution purposes. In addition, without any human intervention, these cameras are capable of interpreting guiding objects and labels. These properties of smart cameras are influencing how technology can be utilized across various industrial sectors.

In 2024, the quality assurance and inspection segment led the 3D machine vision market by holding the largest market share. The growth of the segment can be linked to the growing focus on product quality and compliance across different end-user industries like packaging and labeling, and automotive. Also, market players prioritize adherence to strict quality standards to decrease costs related to returns and rework, which impels them to adopt 3D machine vision systems.

The identification segment is estimated to grow at the fastest rate over the forecast period. The growth of the segment can be driven by the growth of the e-commerce industry and the surge in the need for precise order fulfillment. Additionally, organizations rely more on automated systems for managing and tracking inventory, which makes identification technologies important.

The automotive segment dominated the 3D machine vision market in 2024. The dominance of the segment is owing to the growing use of 3D Machine vision systems in this industry for inspection purposes, which consists of assembly verification, error proofing, absence/presence checking, and final inspection. Moreover, the need for mechanized imaging is substantial across the automobile sector and is expected to grow substantially.

The food and beverage segment is anticipated to grow at the fastest rate over the forecast period. The growth of the segment is due to the rising demand for automation, quality control, and efficiency in areas such as sorting, packaging, and inspection. Furthermore, this technology can be extensively utilized in packaging and bottling operations for tasks such as barcode recognition, label scanning, and defect detection.

By Offering

By Product

By Application

By End Use

By Region

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

October 2024

December 2024

October 2024

October 2023