January 2025

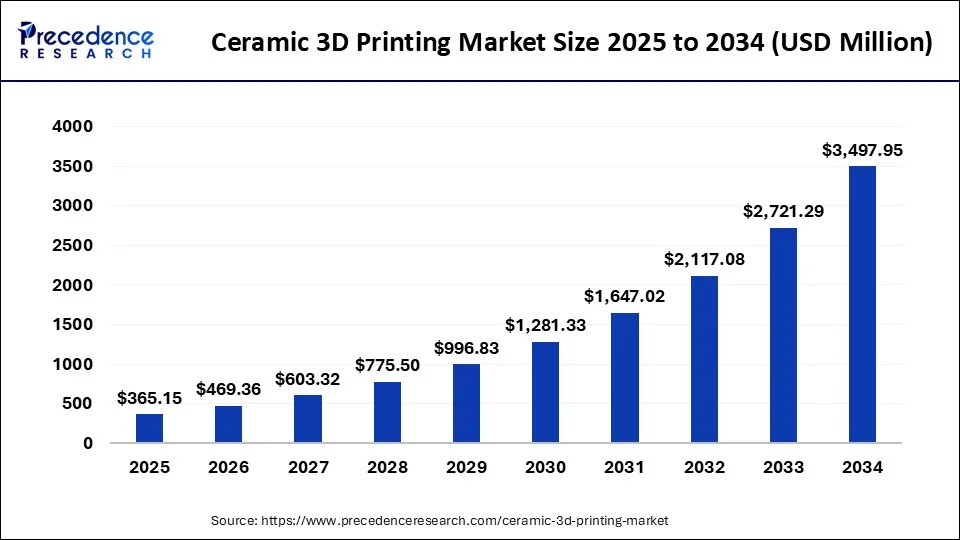

The global ceramic 3D printing market size accounted for USD 284.07 million in 2024, grew to USD 365.65 million in 2025 and is projected to surpass around USD 3497.81 million by 2034, representing double-digit CAGR of 28.52% between 2024 and 2034. The Europe ceramic 3D printing market size is evaluated at USD 99.58 million in 2024 and is expected to grow at a notable CAGR of 28.68% during the forecast year.

The global ceramic 3D printing market size is calculated at USD 284.07 million in 2024 and is predicted to reach around USD 3497.81 million by 2034, expanding at a notable CAGR of 28.52% from 2024 to 2034. Increasing applications of ceramics in industries like automotive, aerospace, and healthcare is the key factor driving the ceramic 3D printing market growth. Also, the introduction of new product launches along with the increasing awareness of the benefits of 3D printing is expected to fuel market growth shortly.

The integration of artificial intelligence (AI) has substantially impacted the ceramic 3D printing market. AI-powered software has enhanced the efficiency, speed, and accuracy of ceramic 3D printing processes. Furthermore, these innovations improved the quality of printed ceramics and also enabled complex designs. The adoption of AI technology has also cut the overall production cost and optimized the whole process significantly.

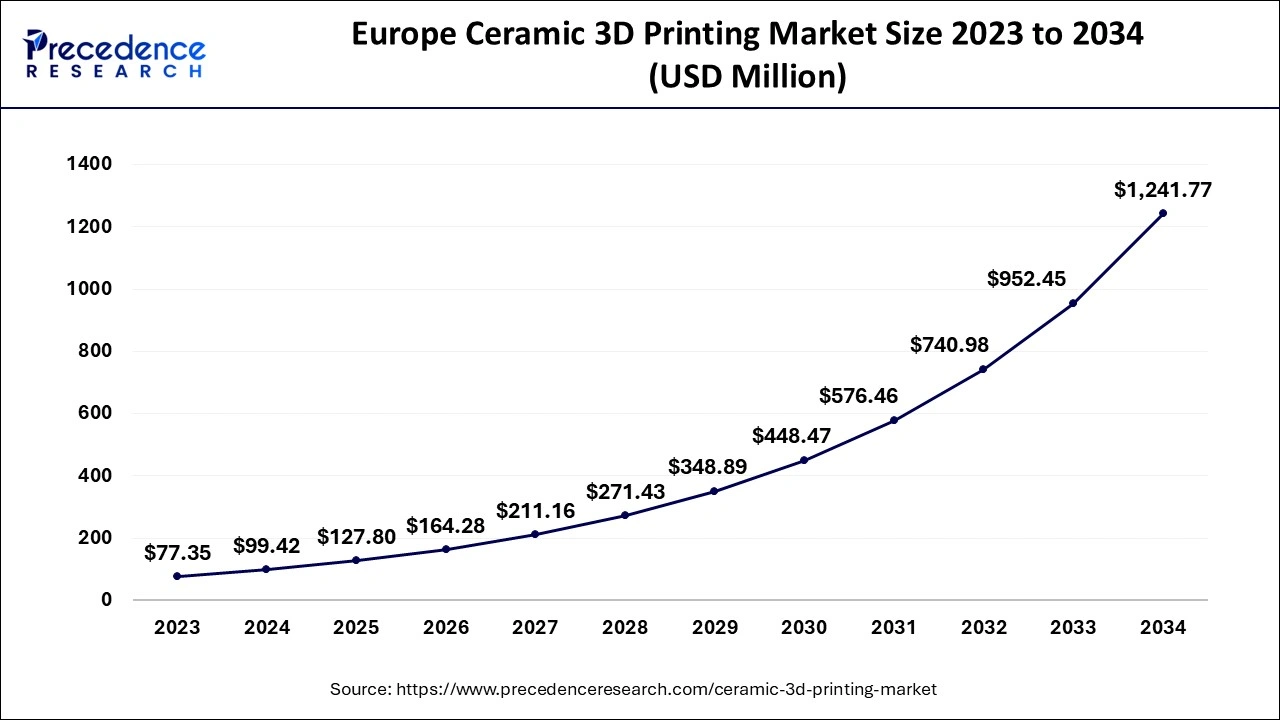

The Europe ceramic 3D printing market size is exhibited at USD 99.58 million in 2024 and is expected to be worth around USD 1,241.72 million by 2034, growing at a double-digit CAGR of 28.68%.

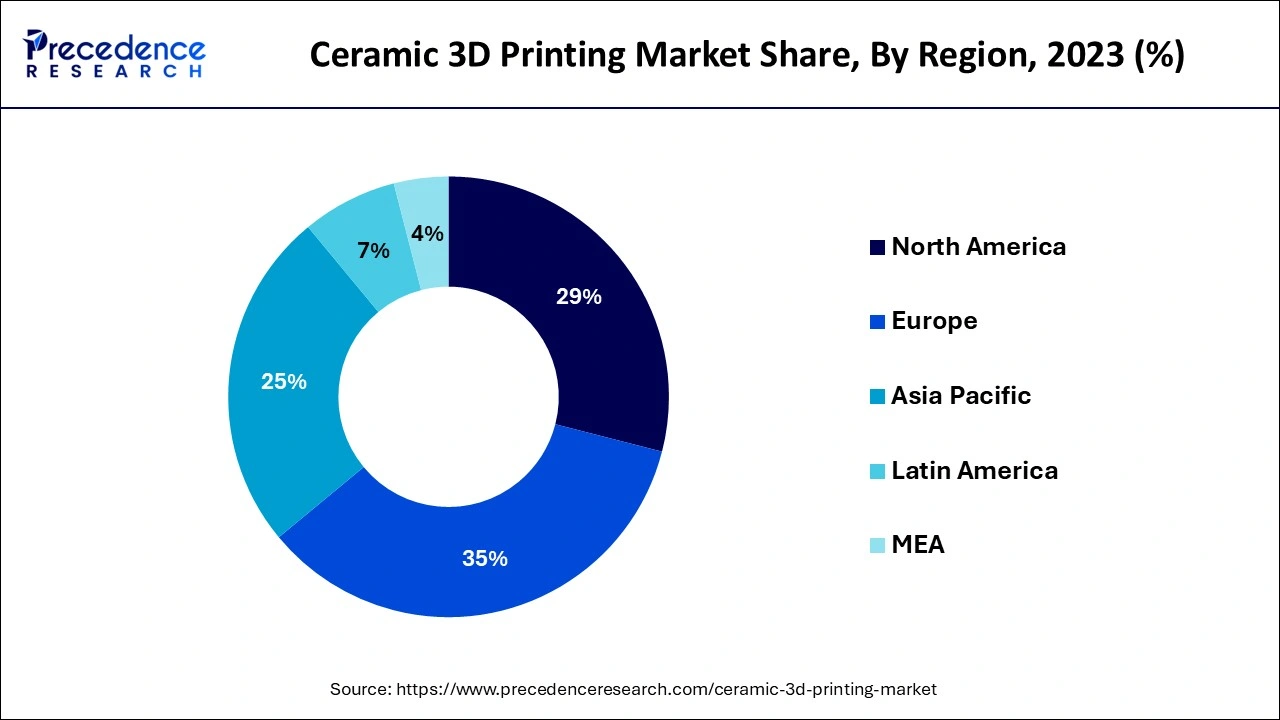

Europe dominated the ceramic 3D printing market in 2023. The dominance of the segment can be attributed to the region's expanding manufacturing industry and its increasing focus on advanced technology adoption. Furthermore, the research institutions and market players are working together to create innovative ceramic 3D printing solutions. Also, the region’s automotive, healthcare, and aerospace industries are rapidly expanding.

Asia Pacific is expected to show the fastest growth in the ceramic 3D printing market over the projected period. The growth of the region can be driven by the region's growing need for ceramic 3D printing applications in industries like automotive and electronics. Moreover, nations such as China and Japan have invested heavily in innovative manufacturing technologies.

The ceramic 3D printing market is an expanding segment of the 3D printing industry that utilizes 3D printers to make ceramic objects. 3D printing provides many benefits over conventional manufacturing methods, such as cost-effectiveness, raised efficiency, and customizability. The market uses various raw materials such as solvent-based, oil-based, and water-based formulations for creating ceramic objects. 3D ceramic printers have applications in several industries like healthcare, automotive, and aerospace.

Top Exporters of Ceramic Products in 2023

| Country | Exports in millions |

| China | USD 26 million |

| Italy | USD 5.81 million |

| Spain | USD 4.75 million |

| Germany | USD 4.28 million |

| India | USD 3.05 million |

| Report Coverage | Details |

| Market Size by 2034 | USD 3,497.81 Million |

| Market Size in 2024 | USD 284.07 Million |

| Market Size in 2025 | USD 365.65 Million |

| Market Growth Rate from 2024 to 2034 | CAGR of 28.52% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Form, Application, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East, and Africa |

Rising demand for customization

It is possible to create complex and customized ceramic goods with the ceramic 3D printing market technologies, which are difficult to make with traditional production techniques. The growing demand for intricate and personalized ceramic parts is rapidly stimulating the adoption of this new technology. In addition, this surge in demand increases from markets such as aerospace, automotive, and healthcare.

High-temperature resistance requirement

The ceramic 3D printing market products demand high temperatures to gain their functionality and strength. This creates a substantial hurdle in 3D printing because it necessitates printers capable of controlling high temperatures consistently over the whole process, which is quite expensive and technically challenging. Moreover, ceramic materials are brittle, which makes them difficult to handle.

Advancements in ceramics material-based 3D printing technologies

The ceramic 3D printing market has witnessed significant growth because of innovation in technology, especially in laser-based ceramic 3D printing. Furthermore, the range of applications of this technology has expanded with the launches of enhanced materials containing special characteristics such as high strength and heat resistance. Due to the latest 3D printing software and hardware technologies, the overall process of manufacturing has become more accessible and efficient.

The powder segment dominated the ceramic 3D printing market in 2023. The dominance of the segment can be attributed to the ongoing development of new ceramic powders that can be utilized in part production and tooling. Also, the powder segment has an established presence in the market. Additionally, the powder-based 3D printing technique is preferred by aerospace, automotive, and healthcare industries because it provides accuracy and high resolution.

The resin segment is anticipated to grow at the fastest rate in the ceramic 3D printing market over the forecast period. The growth of the segment can be credited to the increasing use of resin-based printing in applications such as electronics and medicine. Some market players are also introducing new resins for additive production processes. Moreover, ceramic-based resins can also be used for designs and art applications. This form of ceramic is well-suited for applications such as jigs, fixtures, and tooling.

The rapid prototyping segment led the global ceramic 3D printing market in 2023. The dominance of the segment is because rapid prototyping is utilized in numerous casting and biomedical molds due to its exceptional surface finish. This segment also enables manufacturers of complex and large parts to discard the repetitive process and costly re-tooling during the production process. This process is popular in developing new and innovative designs before utilizing costly tools.

The tooling segment is anticipated to grow at the fastest rate in the ceramic 3D printing market during the projected period. The growth of the segment can be driven by the increasing use of ceramic 3D printing in various tooling applications. Tooling is a segment that manufacturers utilize to create other parts, either by forming them directly or by creating a mold. The dental industry is increasingly using 3D printing to create oral implants that look like the original teeth.

The aerospace & defense segment held the largest share of the ceramic 3D printing market. The dominance of the segment can be linked to the increasing demand for lightweight, high-strength ceramic components from the aerospace and defense industry. Furthermore, this market is heavily investing in cutting-edge materials and technology, marking its place as the leading end-use segment in the market.

The healthcare segment is estimated to grow at the fastest rate in the ceramic 3D printing market during the projected period. The growth of the segment is due to the growing demand for complex and personalized ceramic components in dental and medical applications. Also, ceramic 3D printing is a first choice in making dental implants and orthopedic implants along with prosthetics because it offers accurate and sophisticated manufacturing capabilities.

By Form

By Application

By End-use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

August 2024

February 2025

February 2025