November 2023

Dimethyl Carbonate Market (By Grade: Battery Grade, Industry Grade, Pharmaceutical Grade; By End use: Pharmaceutical, Agrochemicals, Paints & Coating, Battery, Plastics, Others,) - Global Industry Analysis, Size, Share, Growth, Trends, Regional Outlook, and Forecast 2024-2034

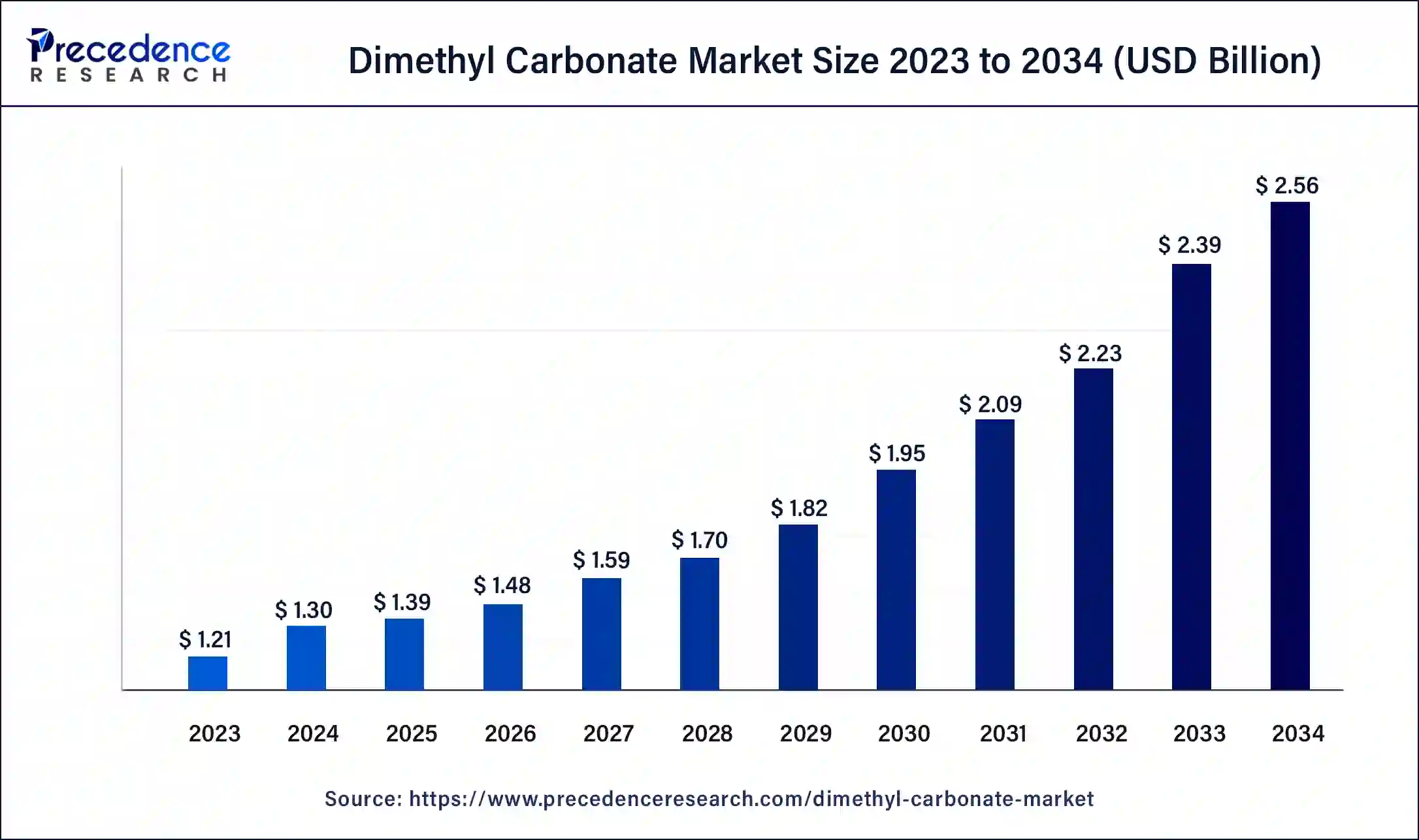

The global dimethyl carbonate market size was USD 1.21 billion in 2023, calculated at USD 1.30 billion in 2024 and is expected to reach around USD 2.56 billion by 2034, expanding at a CAGR of 7.04% from 2024 to 2034. Considering its low volatility and lack of toxicity, dimethyl carbonate (DMC) is regarded as a green chemical as opposed to conventional solvents.

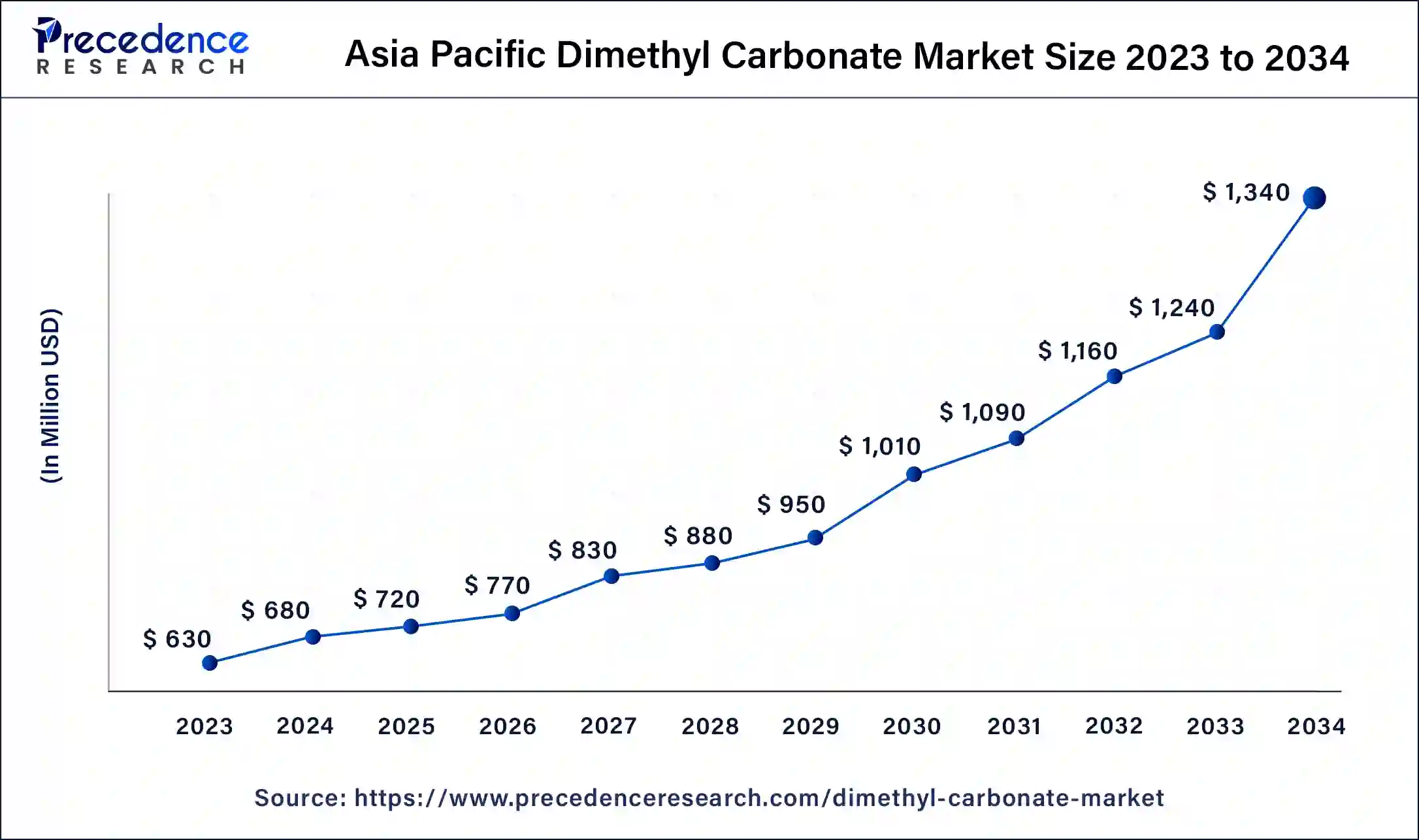

The Asia Pacific dimethyl carbonate market size was exhibited at USD 630 million in 2023 and is projected to be worth around USD 1,340 million by 2034, poised to grow at a CAGR of 7.10% from 2024 to 2034.

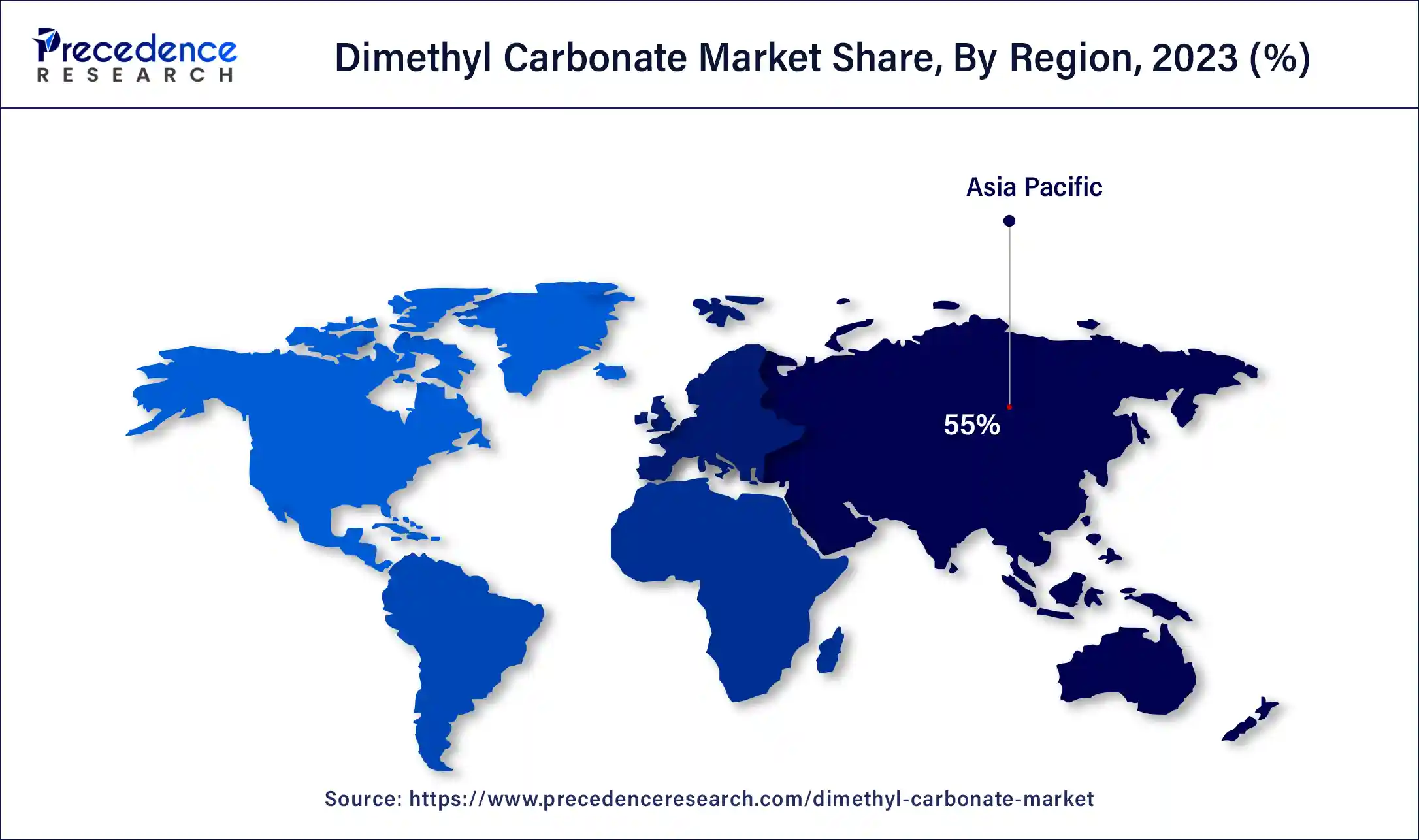

Asia Pacific held the largest share of the dimethyl carbonate market in 2023. A number of reasons are contributing to Asia Pacific’s notable rise in the dimethyl carbonate market. The need for DMC, a solvent used in many industries, including electronics, paints and coatings, and medicines, is being driven by rising industrialization, particularly in nations like China, Japan, India, and South Korea.

The dimethyl carbonate market is expanding because of environmental legislation that supports eco-friendly chemicals since DMC is thought to be a safer choice than conventional solvents. Investments in the energy storage and renewable energy sectors further increase the need for DMC in battery applications.

North America is expected to host the fastest-growing dimethyl carbonate market over the forecast period. Dimethyl carbonate applications in a variety of industries, including electronics, paints & coatings, and pharmaceuticals, have been driving the market's expansion in North America. Growing consumer demand for clean energy sources, stricter laws encouraging eco-friendly products, and growing environmental concerns are all factors driving market expansion.

The rise of dimethyl carbonate in the market is additionally supported by its use in manufacturing processes and its function as a solvent. Growing environmental concerns, regulatory backing for environmentally friendly chemicals, and its use as a versatile solvent and methylating agent are some of the factors driving the market's expansion. A large portion of the global dimethyl carbonate market is accounted for by North America, particularly the United States, because of its strong industrial infrastructure and ongoing research into sustainable chemicals.

The industry that produces distributes, and uses dimethyl carbonate a chemical molecule with a wide range of applications—is referred to as the dimethyl carbonate market. Dimethyl carbonate is frequently utilized as a gasoline additive, solvent, and chemical synthesis intermediate. It is prized for being more ecologically benign than conventional solvents and for being able to substitute more dangerous compounds in a variety of applications. The dimethyl carbonate market includes producers, suppliers, distributors, and consumers from a variety of sectors, including the pharmaceutical, paint and coating, electronics, and automotive industries.

Because DMC is less toxic and more biodegradable than standard solvents, it is becoming more and more popular as an environmentally friendly methylating agent and solvent. The demand for the dimethyl carbonate market is fueled by its importance as an intermediary in the synthesis of polycarbonates, which are utilized in the electronics, construction, and automotive industries. The synthesis of many organic molecules, such as plastics, agrochemicals, and medicines, acts as a flexible chemical intermediary.

Due to a thriving chemical manufacturing industry, Asia Pacific, particularly China, is a major producer and consumer of chemicals. The dimethyl carbonate market is particularly influenced by North America and Europe, where adoption is fueled by strict environmental legislation. DMC is utilized in medicines, lithium-ion battery electrolytes, and organic synthesis processes as a methylating agent in addition to being produced as polycarbonate.

| Report Coverage | Details |

| Market Size by 2034 | USD 2.56 Billion |

| Market Size in 2023 | USD 1.21 Billion |

| Market Size in 2024 | USD 1.3 Billion |

| Market Growth Rate from 2024 to 2034 | CAGR of 7.04% |

| Largest Market | Asia Pacific |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | Grade, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Growing demand for pharmaceuticals

Due to its low toxicity and environmental friendliness when compared to more conventional solvents like methanol, acetone, and dichloromethane, DMC is being employed as a solvent in the pharmaceutical industry more and more. DMC is an essential component in the synthesis of APIs, which is how pharmaceuticals are made. Its methylating and carbonylation properties make it especially useful in the production of pharmaceuticals.

Another important element is the economicality of DMC when compared to other conventional solvents. Manufacturers find it to be an appealing option due to its efficiency in pharmaceutical procedures and comparatively reduced pricing. The dimethyl carbonate market can increase a pharmaceutical process's yield and efficiency.

Raw material price volatility

Since natural gas is a necessary component for the manufacturing of methanol, fluctuations in the price of natural gas can affect the price of methanol, which is a fundamental raw material for the production of DMC. A supply chain disruption could result from anything from natural catastrophes to pandemics to geopolitical tensions. These disruptions could also create abrupt changes in the price and availability of raw materials.

Environmental laws that have an effect on carbon monoxide and methanol production can raise production costs, which in turn can have an impact on DMC pricing. The price of energy used to produce raw materials, especially electricity and natural gas, can have an effect on the dimethyl carbonate market dynamics.

Battery electrolytes

Lithium-ion battery performance and efficiency are greatly dependent on battery electrolytes, among which dimethyl carbonate is a major player in this market. Because of its strong polarity, DMC works well as a solvent for the lithium salts found in battery electrolytes. By doing this, effective ion transport within the battery is ensured.

The steady electrochemical window that the dimethyl carbonate market offers is crucial to the functionality and security of lithium-ion batteries. To maximize the electrolyte's characteristics, DMC is frequently combined with other carbonate solvents such as ethylene carbonate (EC) and propylene carbonate (PC). This combination may enhance the battery's longevity and performance.

The industry segment dominated the global dimethyl carbonate market in 2023. Due to its numerous uses in a variety of industrial processes, the dimethyl carbonate market industry-grade sector is essential. Because of its exceptional solubility and low toxicity, DMC is frequently employed as a solvent in industrial applications. It is frequently used in adhesives, varnishes, and paints. DMC is used as a methylating agent in the synthesis of agrochemicals, specialty chemicals, and pharmaceuticals. It raises the octane number and increases combustion efficiency in gasoline compositions. The need for DMC is fueled by the automotive and aerospace sectors' drive to lightweight materials, which increases demand for polycarbonates.

The pharmaceutical segment is expected to show the fastest growth in the dimethyl carbonate market during the forecast period. Because of its exceptional purity and adaptable chemical characteristics, pharmaceutical grade dimethyl carbonate, or DMC, is essential to the manufacturing of many medications. It functions as a methylating agent throughout the pharmaceutical manufacturing process. Because DMC has less of an adverse effect on the environment and is less hazardous than conventional methylating chemicals like methyl iodide and dimethyl sulfate, it is recommended. The adoption of DMC is accelerated in pharmaceutical applications by favorable regulatory frameworks and approvals. The safety and effectiveness of pharmaceutical-grade DMC are guaranteed by regulatory agencies such as the FDA and EMA. Because of its low toxicity and biodegradability, DMC is a desirable substitute for conventional solvents, supporting the industry's transition to more environmentally friendly and sustainable production methods.

The plastics segment led the dimethyl carbonate market in 2023. DMC is an essential starting material for the production of polycarbonates, which are widely utilized in the plastics industry. Because of their excellent impact resistance and transparency, polycarbonates are used in a variety of products, such as electronic equipment, automobile parts, and eyeglass lenses. New potential for market expansion will arise from advancements in production methods and the creation of new applications for DMC in polymer processing. Finding more effective and environmentally friendly production techniques can result from funding research and development (R&D) for the creation of new and enhanced DMC uses in the plastics sector.

The paints & coating segment is anticipated to grow at a higher CAGR in the global dimethyl carbonate market during forthcoming years. Dimethyl carbonate is becoming more and more popular in the paint and coatings sector because of its beneficial qualities and adaptability. Due to its great biodegradability and low toxicity, DMC is regarded as a green solvent. Compared to conventional solvents like xylene and toluene, it has a less detrimental effect on the environment. Because DMC can be utilized as a solvent, reagent, and intermediary in the synthesis of different chemicals, formulators in the coatings sector have a flexible option. DMC contributes to architectural paints by enhancing the finish and longevity of coatings used on infrastructure and structures. Due to its great solvency and quick drying times, DMC is used in industrial coatings. These qualities are crucial for a number of production processes.

Segment Covered in the Report

By Grade

By End-use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

November 2023

January 2025

January 2025

November 2024