January 2025

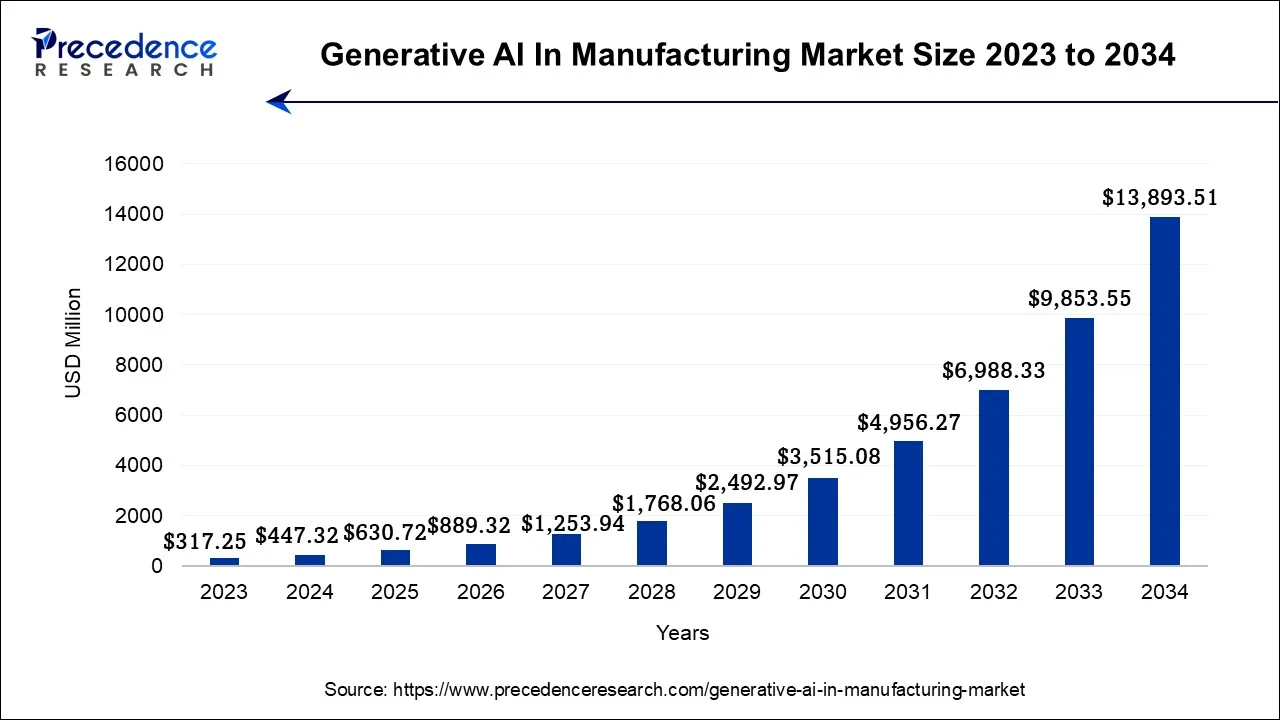

The global generative AI in manufacturing market size is calculated at USD 447.32 million in 2024, grew to USD 630.72 million in 2025, and is predicted to hit around USD 13,893.51 million by 2034, poised to grow at a CAGR of 41% between 2024 and 2034. The North America generative AI in manufacturing market size accounted for USD 201.29 million in 2024 and is anticipated to grow at the fastest CAGR of 41.16% during the forecast year.

The global generative AI in manufacturing market size is expected to be valued at USD 447.32 million in 2024 and is anticipated to reach around USD 13,893.51 million by 2034, expanding at a CAGR of 41% over the forecast period from 2024 to 2034.

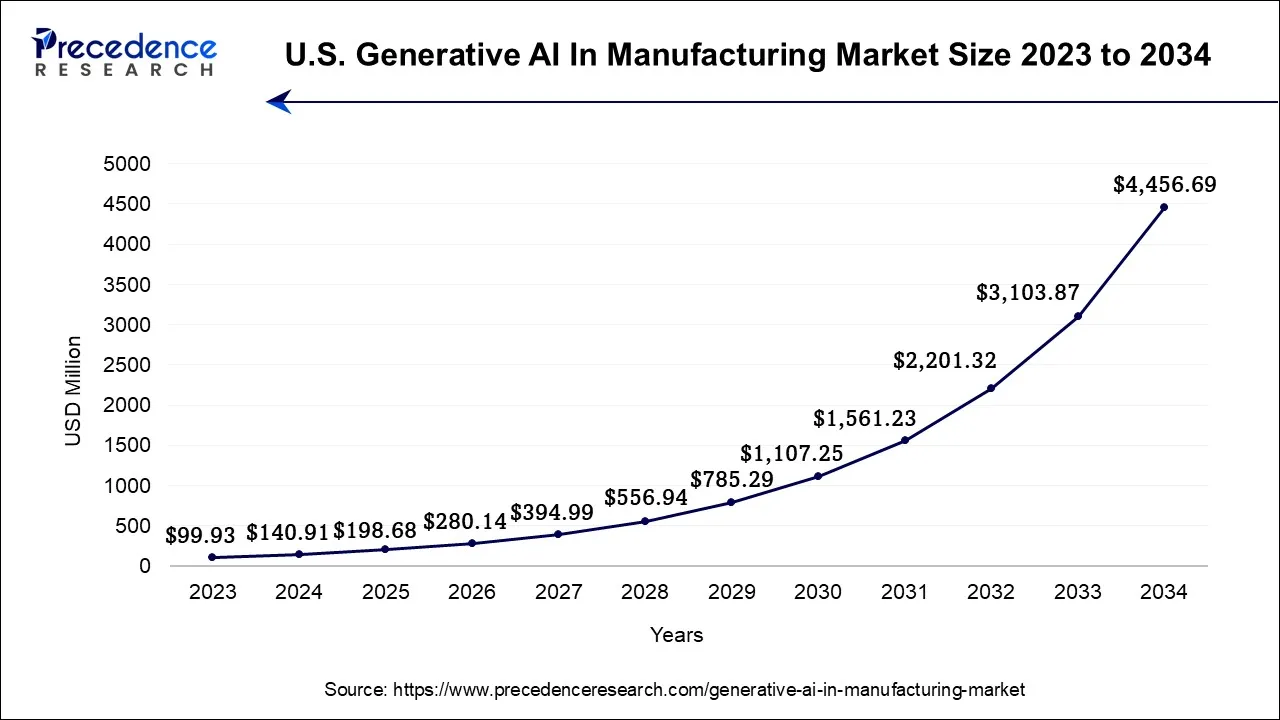

The U.S. generative AI in manufacturing market size is accounted for USD 140.91 million in 2024 and is projected to be worth around USD 4,456.69 million by 2034, poised to grow at a CAGR of 41.26% from 2024 to 2034.

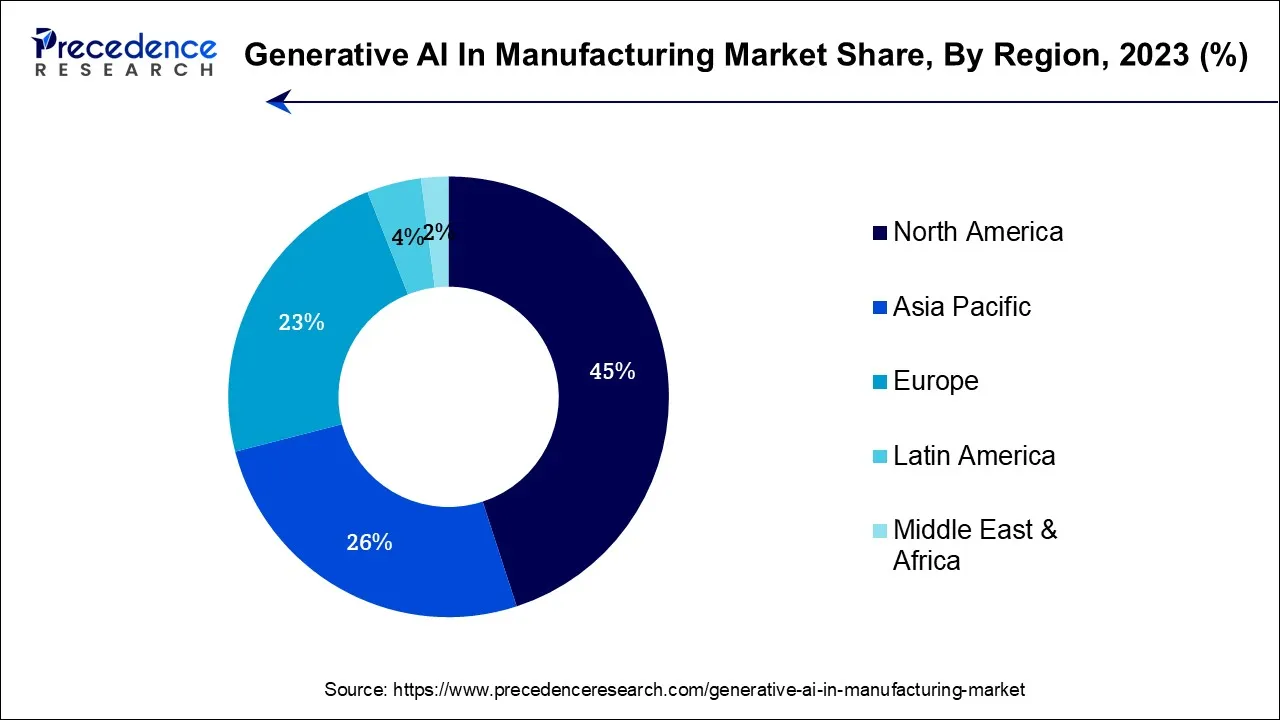

North America dominated the market in 2023, the region is expected to continue its position throughout the forecast period. The growth of the market in North America is attributed to the rising adoption of advanced technologies in the industries and the increasing investment by the major players in the manufacturing industries that are driving the growth of the market. With the presence of most of manufacturing plants situated, the United States and Canada are observed to continue as largest contributors to the market in the upcoming period.

The growth of the market in the region is attributed to the rising population and increased demand for the manufacturing industries for the fulfillment of consumer demand. The rising number of manufacturing industries drives the need for generative AI applications for improved productivity and enhancing customer satisfaction will drive the growth of generative AI in the manufacturing market across the region. Additionally, multiple international players are actively investing in manufacturing facilities in Asian countries due to lower labor costs and availability of raw materials, this element is expected to boost the market’s expansion along with the rapid adoption of artificial intelligence models.

Generative AI, being a prominent branch of artificial intelligence, has been recently adopted by many organizations for the improvement of business operations and increased customer satisfaction. Generative AI helps the organization by creating new inputs by analyzing existing data and records of the organization. Generative AI also helps in the overall process of the manufacturing industry. Generative AI helps in product designing, predictive maintenance, improved efficiency, etc. which helps in driving the growth of generative artificial intelligence (AI) in manufacturing market.

There are several industries such as manufacturing, automotive, aerospace, etc. are implementing generative AI applications for the improvement of business operations. The continuous development of artificial intelligence leads to the advancement of generative AI and the growth of the adaptation of generative AI in the manufacturing industry due to its properties like handling complex data sets and generating more precise and accurate results. There are three main types of generative AI applications in the manufacturing industries such as providing information support, converting information to output, and enhancing robotics.

In the manufacturing industry, generative AI models and tools such as ChatGPT are used for generating automatic text to support operations. Generative AI also can be helped by converting the text to codes or images which will allow organizations to enhance the manufacturing process. With the rising commercialization and product demand, manufacturers are aimed at boosting the pace of manufacturing processes, this brings a growth factor for the global generative AI in the manufacturing market.

Generative AI robotics aids in enabling robots to automatically act on, for instance, voice commands. There are various areas of operation in which generative AI is beneficial for the manufacturing industry which is contributing to the demand of generative AI in manufacturing market.

| Report Coverage | Details |

| Market Size in 2024 | USD 316.13 Million |

| Market Size by 2034 | USD 6,963.45 Million |

| Growth Rate from 2024 to 2034 | CAGR of 41% |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Period | 2024 to 2034 |

| Segments Covered | By Deployment, By Industry Vertical, and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Utilizing AI technologies can improve an organization's analytical capabilities, allowing for greater resource utilization, forecast accuracy, and inventory cost reduction. Better analytics capabilities enable businesses to transition to predictive maintenance, which lowers maintenance expenses and eliminates downtime costs. Robots, however, need CAPEX, which must be compared against the ongoing cost of manpower. In addition, when AI and other automation technologies are used, the chances of workplace accidents and manual errors are eliminated. All these factors create a significant potential for generative AI for the manufacturing industry. Thereby, the element of enhancement in productivity and reduction in cost is considered to act as a driver for the market.

Although the manufacturing sites have a large amount of machinery and equipment in the infrastructure some of the machinery is of outdated software that cannot work with the entire system, which is negatively impacting the growth of the market. In addition, the adoption of generative AI models requires a drastic transformation to a totally new system from the existing system. This can be complicated for multiple manufacturing industries. Additionally, the slower pace of adoption of technology, especially in underdeveloped areas, creates a restraint for the market to expand.

Web3 technologies are being used by businesses to enhance supply chain and logistics procedures. Blockchain technology and smart contracts promise to save costs and administrative time while enhancing data security, traceability, and transparency. Web3 technology leverages the overall capabilities of artificial intelligence models by achieving real-world communication. Real-time tracking of commodities by manufacturing companies using blockchain lowers the possibility of lost or stolen goods and speeds up delivery. The use of less manual documentation and faster processing times can aid with customs clearance as well. Furthermore, smart contracts can automate procedures and lessen the need for middlemen, increasing effectiveness and cutting expenses. Thereby, the penetration of.

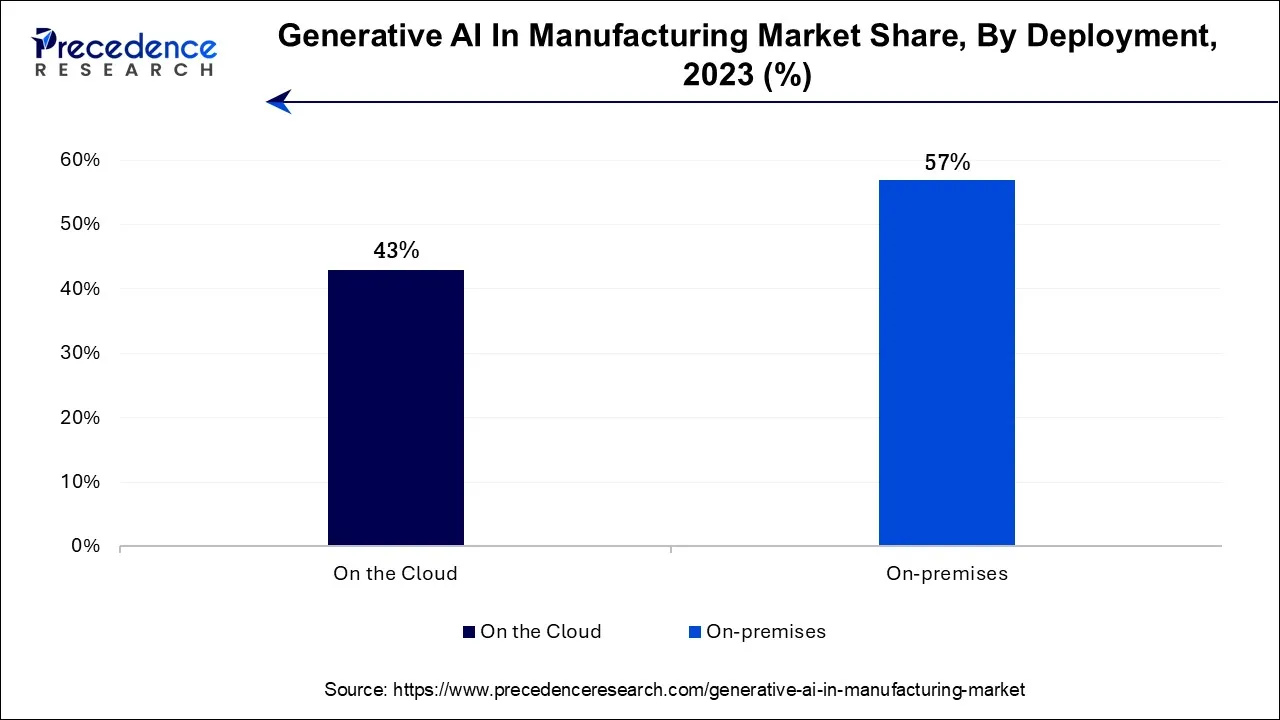

The on-premise segment dominated the market in 2023. On-premise deployment is installing or deploying the software within the infrastructure of the organization. On-premise software is installed on and works within the organization or at a location that is under control. On-premise deployment only works within the area of the organization, it cannot be worked outside the area of an organization. One of the major advantages of on-premise deployment is it offers prominent security and control for the use of its own IT infrastructure for the connection with processes, people, and systems. On-premise deployment works on virtualized servers for simple configuration.

The cloud deployment segment is expected to witness the fastest rate during the forecast period. Cloud technology is frequently adopted by several industries for better management and performance improvement of the organization. It has been seen that the manufacturing industry is going through a major IT transformation, notably cloud computing. The major goal of cloud computing in the organization is scalability, reliability, and on-demand provisioning of resources. Cloud computing plays an important role in the manufacturing industry by increasing agility, expansion of flexibility, and increased productivity with reduced cost.

The automotive segment dominated the market in 2023. There are various automotive companies that are adopting generative AI technology for the improvement of industrial work. The automotive industry mainly utilizes generative AI technology for manufacturing, predictive analysis, and maintenance. One of the primary applications of generative AI in automotive industry is designing and prototyping. In previous times designing was a time-consuming process that took more effort by the engineers to make an automobile design, generative AI analyses a large amount of data and generates the latest designs or data by analyzing the existing ones. Generative AI can be helpful in autonomous vehicles by real-time decision-making.

The aerospace segment is expected to grow at a significant rate during the predicted timeframe. The aerospace industry is one of the most advanced and vast manufacturing industries across the globe. Generative AI plays an important role in product design, efficient supply chain management, training, fuel efficiency, and improving customer satisfaction. Generative AI is a technological innovation that improves productivity as well as the speed and development of the aerospace industry. Generative AI is highly beneficial for reducing the time of the design process, reduction of costs, prototyping, reproduction, support, enhancement, manufacturing, and updating items which are driving the growth.

The product design segment dominated the market in 2023. The growth of the segment is attributed to the substantial demand for generative AI technology in the improvement of product designing in manufacturing industries. Product designing is the process in which there is a continuous requirement for the creation of innovative designs that meet the demands of the user. Organizations use various ways to enhance product designs in which the generative AI helps in the improvement of overall quality of product design. Generative AI uses artificial intelligence algorithms to generate new designs, ideas, and solutions. Generative AI has revolutionized the process of designing. Generative AI automates the design task, exploring a large number of possibilities, and optimizes the design.

The predictive maintenance segment is expected to increase its market share during the forecast period. Generative AI in predictive maintenance in the manufacturing industries by finding opportunities for the improvement of the workforce or customer productivity. Organizations implement predictive maintenance to analyze the vast amount of existing or historical data for the identification of anomalies and patterns. Predictive maintenance predicts the failures of equipment before they occur and allows for proactive maintenance action.

Market Segmentation

By Deployment

By Industry Vertical

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

July 2024

September 2024

January 2025