April 2025

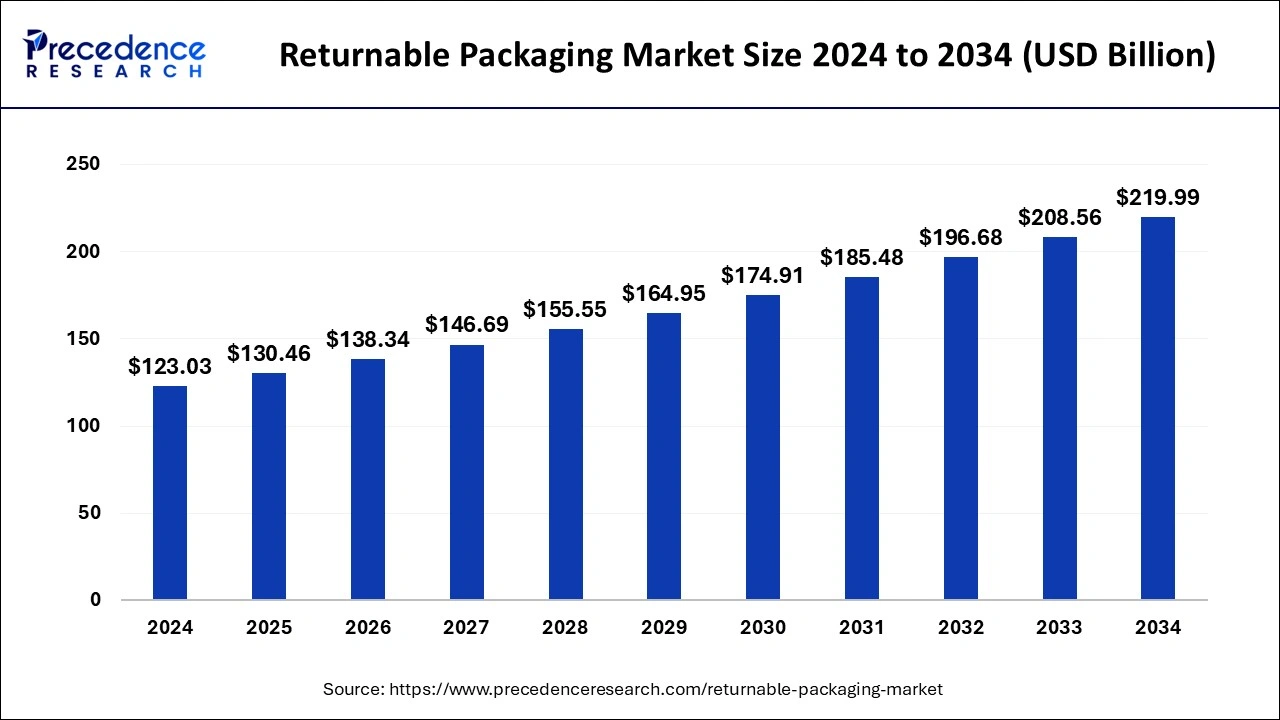

The global returnable packaging market size is estimated at USD 130.46 billion in 2025 and is predicted to reach around USD 219.99 billion by 2034, accelerating at a CAGR of 5.98% from 2025 to 2034. The Asia Pacific returnable packaging market size surpassed USD 49.57 billion in 2025 and is expanding at a CAGR of 6.12% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global returnable packaging market size was calculated at USD 123.03 billion in 2024 and is expected to reach around USD 219.99 billion by 2034, expanding at a CAGR of 5.98% from 2025 to 2034. The growth of the returnable packaging market is driven by the rising demand for sustainable packaging solutions and the growing focus on reducing packaging waste.

The use of artificial intelligence (AI) in returnable packaging businesses helps optimize delivery processes while managing stock better and using materials more effectively. AI technologies help companies create better packaging designs while using less material and resources. Advanced technologies like AI and ML help manufacturers create reusable packaging solutions that meet strict environmental regulations while working well for multiple usage types. Moreover, integrating AI technologies in the production processes of returnable packaging automates processes and reduces waste generation, thereby enhancing production efficiency.

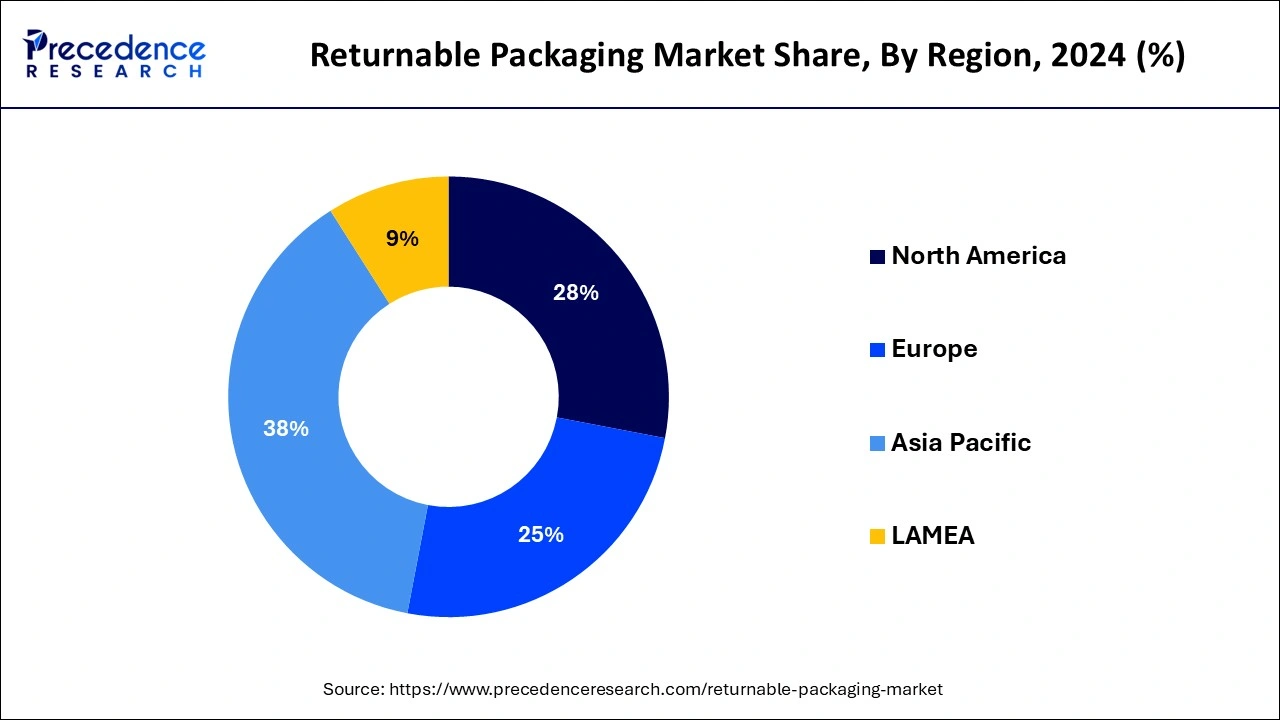

The Asia Pacific returnable packaging market size was exhibited at USD 46.75 billion in 2024 and is projected to be worth around USD 84.69 billion by 2034, poised to grow at a CAGR of 6.12% from 2025 to 2034.

Asia Pacific dominated the returnable packaging market in 2024. Asia Pacific has seen tremendous urbanization and industrial expansion, which has raised demand for effective packaging solutions in a number of sectors, including manufacturing, electronics, and the automobile industry. Due to increased internet usage and consumer spending, e-commerce has flourished in the area. In this rapidly expanding industry, returnable packaging is crucial for the economical and efficient transportation of goods.

Major hubs for export and manufacturing include China, India, Japan, and South Korea. Reusable and dependable packaging solutions are essential for the economical and secure transportation of products. In Asia Pacific, environmental impact reduction and sustainability are becoming more and more important. The returnable packaging market is being embraced by businesses and governments as a way to reduce waste and encourage the circular economy.

North America is expected to witness significant growth in the returnable packaging market during the forecast period. The automotive, aerospace, pharmaceutical, and consumer goods sectors are just a few of the well-established businesses found in North America, especially in the United States and Canada. The market for returnable packaging is expanding as a result of these sectors' need for robust and effective packaging solutions.

In North America, there is a considerable emphasis on environmental effect reduction and sustainability. The returnable packaging market is becoming more and more popular among businesses as a way to reduce waste and encourage environmentally friendly behaviors that also comply with legal requirements and corporate social responsibility objectives. The area has a well-established logistics and supply chain, which facilitates the effective use of returnable packaging technologies. The modern logistics networks make it easier to organize, trace, and return recyclable packaging.

The returnable packaging market refers to the sector of reusable packaging, which is a term used to describe packing materials intended to be reused several times before being discarded or recycled. The materials used to make these kinds of packaging are usually strong enough to endure handling and frequent usage.

The reusable packaging is frequently utilized in a variety of sectors to save waste, minimize packaging expenses, and enhance environmental sustainability. The returnable packaging is a popular choice for many sectors looking for environmentally friendly packaging solutions since it has several benefits, including operational, economic, and environmental ones.

The returnable packaging market is fragmented with multiple small-scale and large-scale players, such as ORBIS Corporation, NEFAB GROUP, PPS Midlands Limited, Tri-pack Packaging Systems Ltd., Amatech, Inc., CHEP, Celina, UBEECO Packaging Solutions, RPR Inc., RPP Containers, IPL, Inc., Schoeller Allibert.

| Report Coverage | Details |

| Market Size in 2025 | USD 130.46 Billion |

| Market Size in 2034 | USD 219.99 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 5.98% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Material, Product, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Growing retail and e-commerce sectors

The growing retail and e-commerce sectors boost the returnable packaging market. The need for effective and affordable packaging solutions has grown due to the retail and e-commerce sectors' explosive expansion. In these quick-paced industries, returnable packaging contributes to increased logistical efficiency, decreased packaging waste, and cheaper shipping expenses.

Costs of the initial investment

A few organizations in the returnable packaging market may find it prohibitive to incur the upfront expenditures of installing returnable packaging solutions, which include buying sturdy containers and establishing reverse logistics procedures. Budgetary restrictions or concerns about return on investment (ROI) may cause businesses to pause.

Sensitive product protection and superior quality

The sensitive product production and superior quality can boost the returnable packaging market. Reliable and secure packaging solutions are necessary for industries that deal with high-value and delicate items, such as electronics, chemicals, and medicines. High-quality protection against contamination and damage during transit is offered by returnable packing.

The plastic segment dominated the returnable packaging market in 2024. Returnable plastic packaging, such as crates, pallets, and containers, is incredibly strong and can endure repeated usage without suffering from severe damage. Because of its durability, firms wishing to invest in reusable packaging solutions may do so at a reasonable price. Compared to other materials like metal or glass, plastic is substantially lighter. These lightweight characteristics ease handling and lower transportation costs, which improves operational efficiency.

Plastic is versatile and can be molded into a broad range of sizes and forms, meeting the needs of many industries and applications. Because of its adaptability, it may be tailored to certain industries, such as the food and beverage, automotive, electronics, or retail sectors. Plastic returnable packaging can have a high initial cost, but because of its reusability, decreased damage rates, and lessened shipping, there are long-term cost advantages.

The metal segment is expected to grow at the highest CAGR in the returnable packaging market during the forecast period. Metal packaging is incredibly strong and resilient, able to handle challenging circumstances and large weights. This makes it perfect for sectors like heavy machinery, industrial products, and automobiles that need robust packaging solutions. Steel racks, aluminum containers, and metal pallets are examples of returnable packaging made of metal that usually lasts longer than other materials.

Over time, this long-term use increases productivity and reduces costs. Metals are good for moving big, heavy objects because they can support large weight loads without fracturing or deforming. This is especially crucial for industries like aerospace and automotive. Packaging made of metal is resistant to corrosive conditions, impacts, and high temperatures. Because of its robustness, it may be used in industries with demanding standards and challenging operating environments.

The pallets segment dominated the returnable packaging market in 2024. Pallets are an essential part of supply chain logistics in a number of sectors, such as manufacturing, food and beverage, retail, and pharmaceuticals. Because of their adaptability, they are essential for moving a variety of goods. Pallets help transport items with forklifts, pallet jacks, and automated warehouse systems more easily and efficiently. This increases the efficiency of logistics overall, lowers labor costs, and speeds up loading and unloading times.

Pallets are available in standard sizes, which facilitates operations, maximizes storage capacity, and guarantees interoperability with international shipping containers and transit networks. The smooth incorporation of these standards into supply chains is essential. Returnable pallets are built to be strong and resilient, especially if they are composed of plastic and metal. Their sturdy design lessens the need for frequent replacements, which raises the price.

The IBC segment is expected to grow at the highest CAGR in the returnable packaging market during the forecast period. IBCs are extremely adaptable and found in many different industries, including agriculture, food & beverage, chemicals, and pharmaceuticals. Their versatility in storing and moving both liquids and solids makes them essential in many industries.

IBCs are significantly less expensive than conventional packaging options. Because of its huge capacity, fewer smaller containers are required, which results in less money spent on handling, storing, and shipping. IBCs are made of sturdy materials that are meant to last and be reused, such as metal or high-density polyethylene (HDPE). When compared to solutions for single-use packaging, this longevity guarantees a superior return on investment. Because of their stackable shape, IBCs maximize storage capacity both during transit and in warehouses. This effective use of space is especially advantageous for companies trying to get the most out of their storage capacity.

The food & beverage segment dominated the returnable packaging market in 2024. The food and beverage sector handles a lot of products every day; thus, effective and dependable packaging solutions are needed to guarantee secure storage and transit. Strict safety and sanitary regulations apply to the sector. Plastic crates, pallets, and bins are examples of returnable packing options that are readily sterilized and reused while adhering to health laws.

Packaging that may be returned lowers the costs of single-use packaging, including ongoing purchases and disposal charges. This cost-effectiveness is essential in a sector where profit margins are narrow. In an effort to lessen its influence on the environment, the food and beverage sector is placing a greater emphasis on sustainability. Returnable packaging helps these efforts by cutting down on waste and the requirement for raw materials.

The healthcare segment is expected to grow at the highest CAGR in the returnable packaging market during the forecast period. Medical supply and prescription drug packing and delivery are governed by stringent laws that apply to the healthcare business. In order to guarantee compliance and safety, returnable packaging solutions may be created to match these strict requirements. Healthcare goods such as medications and medical gadgets are frequently expensive and environmentally sensitive.

Delivered in returnable packing, there is less chance of damage and contamination since it offers better stability and protection. Reducing its environmental impact is driving the healthcare business to embrace more sustainable methods. Because it reduces waste and encourages the reuse of packaging materials, returnable packaging supports these efforts.

By Material

By Product

By End-use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

April 2025

April 2025

January 2025

March 2025