July 2024

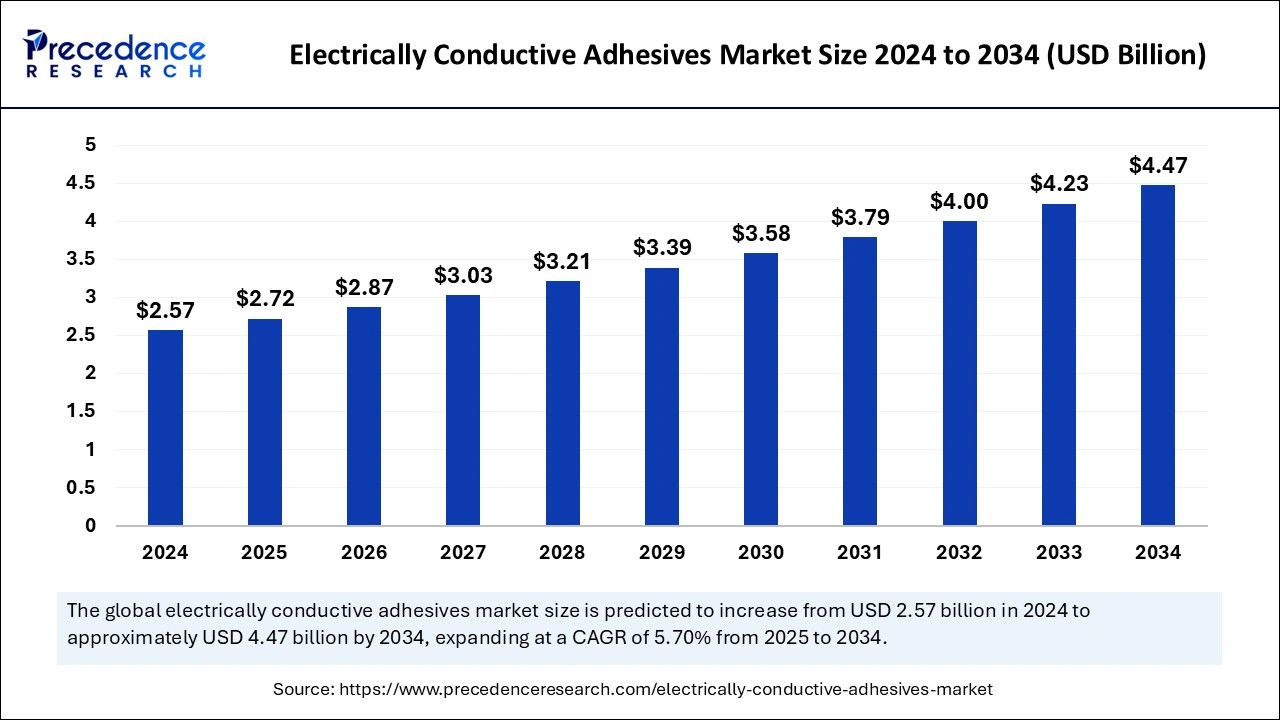

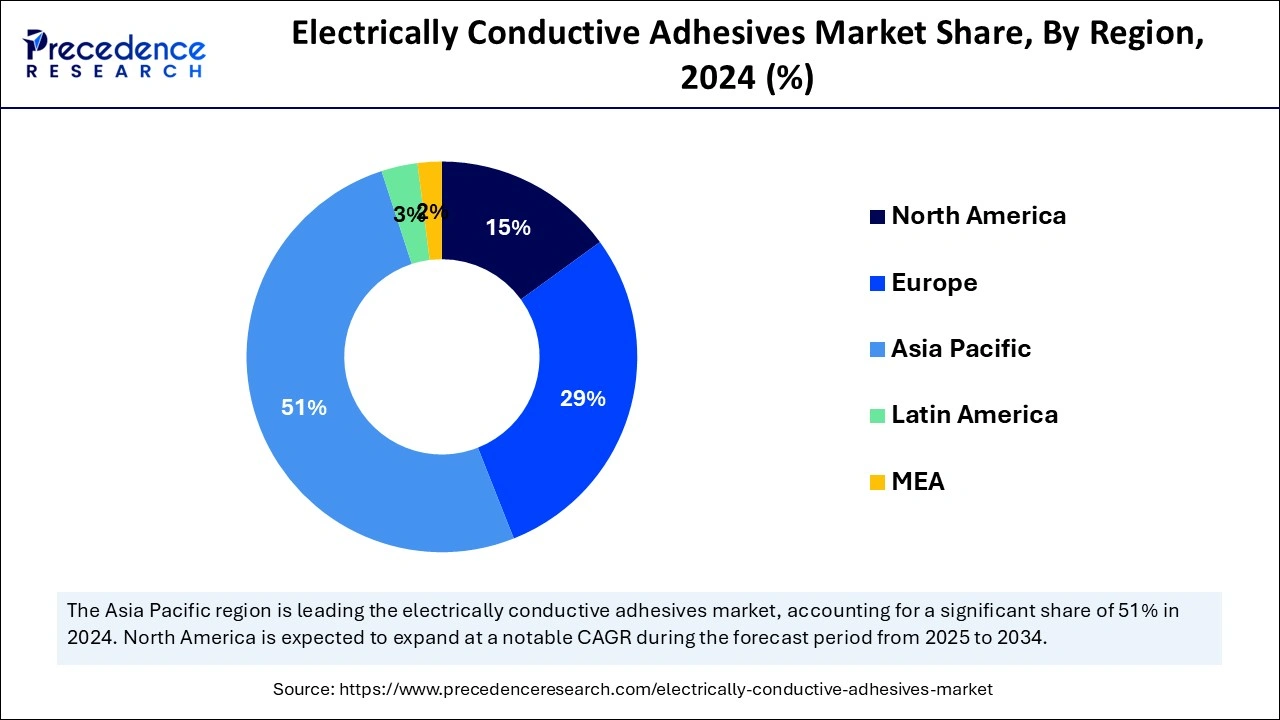

The global electrically conductive adhesives market size is calculated at USD 2.72 billion in 2025 and is forecasted to reach around USD 4.47 billion by 2034, accelerating at a CAGR of 5.70% from 2025 to 2034. The Asia Pacific market size surpassed USD 1.31 billion in 2024 and is expanding at a CAGR of 5.79% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global electrically conductive adhesives market size was calculated at USD 2.57 billion in 2024 and is predicted to increase from USD 2.72 billion in 2025 to approximately USD 4.47 billion by 2034, expanding at a CAGR of 5.70% from 2025 to 2034.The market is driven by the growing demand for smaller, efficient electronics, the growth of electric vehicles, technological advancements, and the expanding use of renewable energy technologies.

The implementation of artificial intelligence within the electrically conductive adhesives market drives significant advancements throughout product design and production operations, together with quality assurance systems. Machine learning algorithms evaluate significant data volumes to develop optimized adhesive formulations that provide improved electrical conductivity with durability functions and processing effectiveness.

AI improves production processes by deploying real-time manufacturing line monitoring systems that detect defects while maintaining consistent product quality. AI systems analyze adhesive applications to identify very small inconsistencies, which enables product reliability maintenance at the highest standard. The market receives vital support from artificial intelligence technology as industries push their requirement toward advanced materials.

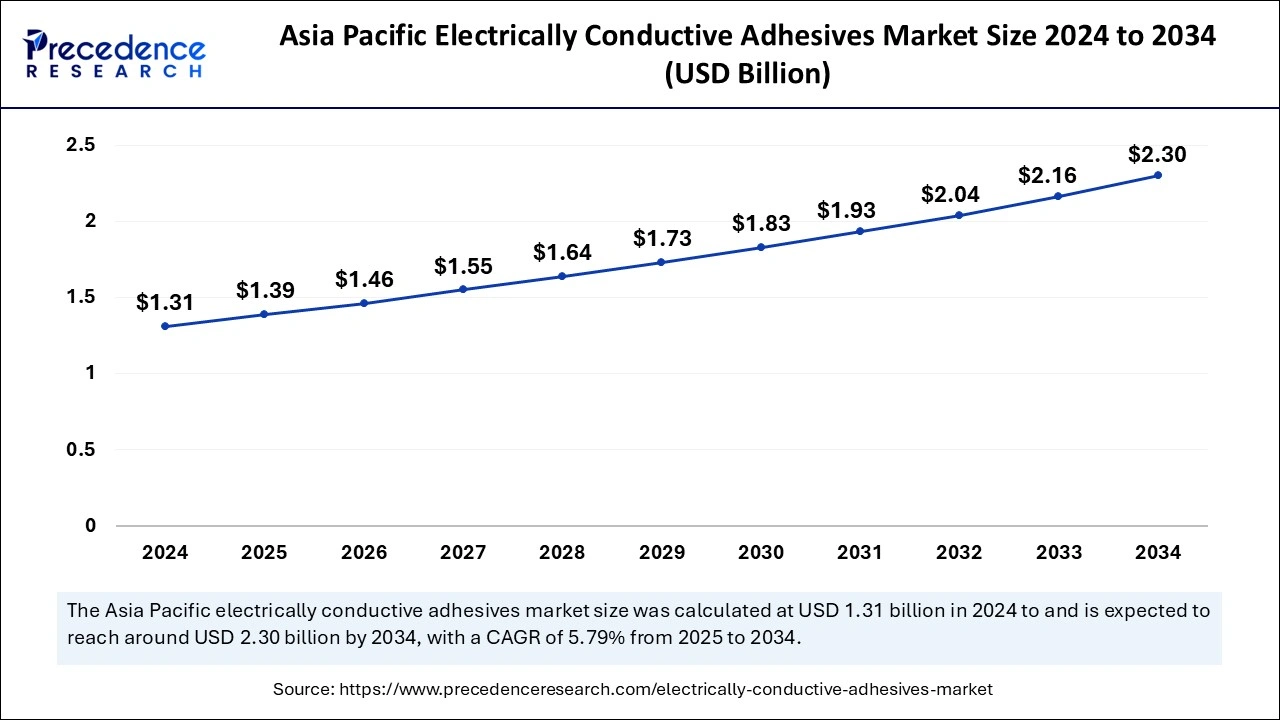

The Asia Pacific electrically conductive adhesives market size was exhibited at USD 1.31 billion in 2024 and is projected to be worth around USD 2.30 billion by 2034, growing at a CAGR of 5.79% from 2025 to 2034.

Asia Pacific accounted for the largest electrically conductive adhesives market share in 2024. The surge of technological innovations combined with the maximum concentration of electronic companies throughout China, South Korea, India, and Japan. The market benefits from expanding electronics and automotive industries that result from rapid development through industrialization and urbanization across regions.

The combination of rising network connectivity initiatives with advanced technological advancements induces regional manufacturers to use circuit boards. The market growth in this region gets boosted through increased production speed, government assistance, and the widespread use of computing devices alongside smartphones and gaming products. During the upcoming period, the market will experience expansion because of the growing Asia Pacific industries focused on automotive and aerospace technology sectors.

North America is anticipated to witness rapid growth in the electrically conductive adhesives market during the forecasted years. to its robust industrial sector and technological advancements. The increasing electronic product requirements and North America’s ongoing industry innovation across automotive, telecommunications, and renewable energy sectors. The increasing need for electronic devices to become smaller with stronger and more efficient parts leads to increased manufacturing use of electrically conductive adhesives.

The North American investment in electric vehicles and advanced automotive technologies has pushed the market toward utilizing electrically conductive adhesives for electronic component bonding, resulting in better performance and more connected systems. The market expanded due to major manufacturers with research facilities operating within the United States and Canada.

Conductive adhesives consist of two major components, one of which is an adhesive base matrix and the other a conductive metal filler. Electronic and electrical component joining requires electrically conductive adhesives. The adhesives serve circuit assembly requirements, which require heat curing and hot soldering methods. The filling components of this material include silver, copper, graphite, and nickel. The mixture includes fillers that enable easy electrical conduction while ensuring outstanding adhesive capabilities and the required physical quantities.

Epoxy and silicon-based electrically conductive adhesives are used throughout the construction, aerospace, and electronics sectors. The electrically conductive adhesives market has demonstrated a notable expansion in recent years while anticipating continued growth during future periods. This growth can be attributed to manufacturers constantly seeking to produce miniaturized electronic devices like smartphones with lightweight equipment, including tablets and wearable devices. The market value further expands due to two major developments: the rising popularity of electric-powered vehicles and the rising need for renewable power generation equipment.

| Report Coverage | Details |

| Market Size by 2034 | USD 4.47 Billion |

| Market Size in 2025 | USD 2.72 Billion |

| Market Size in 2024 | USD 2.57 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 5.70% |

| Dominating Region | Asia Pacific |

| Fastest Growing Region | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Chemistry, Filler, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Growing demand for miniaturization in electronic devices

The electrically conductive adhesives market will be boosted by the ongoing miniature device development trend in electronics. Manufacturers use electrically conductive adhesives to create electronic systems of reduced size and weight, along with superior processing speed, efficiency, and increased power output at lower energy usage. Multiple electric adhesive products of different sizes and forms serve electronic devices across various applications. The electronics sector experiences increased growth because users require smaller automated mobile devices as well as touchscreen interfaces and medical electronics equipment.

The rise in product demand triggered an increase in electronic adhesive consumption. ECAs serve as connection agents between electronic components while playing an essential role in modern technical miniaturization. The increasing technological advancements require further development of adhesive performance standards for high-performance applications alongside sufficient end-result capabilities. The requirements from adhesive manufacturers increase to enhance thermal conductivity and electrical conductivity alongside extreme environment durability, optical clarity, and fast curing times.

Supply chain challenges and raw material price volatility

The electrically conductive adhesives market faces significant barriers because of supply chain challenges, raw material prices, and broader supply chain dynamics. The manufacturing process of electrically conductive adhesives depends on conductive fillers such as silver, copper, and carbon alongside curing agents and resins. Silver and other precious metals show price volatility, which increases production expenses for the electrically conductive adhesive industry. The essential market components experience negative impacts in terms of availability and cost because of geopolitical tensions, natural resource shortages, and labor disruptions, so these factors restrict market growth potential.

Growth of the aerospace sector

Electrically conductive adhesives market applications serve the aerospace industry as vehicle components for static electricity grounding while also functioning to disperse such charges and create shield-based protection. Electrically conductive adhesives consist of epoxy polymers with high strength and dimensional stability to bond incompatible materials that usually appear in aerospace applications.

Electrically conductive adhesives serve as a key driver for aerospace industry expansion through their ability to build safer electronic elements that use aircraft and spacecraft platforms, although soldering methods prove inadequate because of fragile materials and intricate shape designs. This requirement creates rising market demand since aerospace technology aims for more complex systems. The rising aircraft production will further boost the demand for electrically conductive adhesives.

The isotropic conductive adhesives segment generated a significant share of the electrically conductive adhesives market in 2024. Isotropic conductive adhesives are a type of electrically conductive adhesive (ECA) that uses metallic fillers inside a polymeric system to transmit electrical current. Isotropic conductive adhesives are used in applications such as chip contacting and bonding electrically conductive SMDs. The market will experience rising demand for Isotropic ECAs due to their expanding uses throughout various end-user sectors. The primary features that ICAs present over conventional soldering techniques are better thermal properties and enhanced mechanical capabilities alongside shortened processing times and the capacity to unite differing materials. ICAs have become standard in electronic manufacturing since they provide efficient electrical connections while supporting the size reduction of electronic devices, encompassing smartphones, tablets, and wearable devices.

The anisotropic conductive adhesives segment is projected to witness the fastest growth over the forecast period. The production of electrical connections between components makes use of Electrically Conductive Adhesives, while Anisotropic Conductive Adhesives represent a variation of these ECAs, which operate as unidirectional conductors. Such materials find application in systems that demand controlled electrical conduction. Electronic devices that include smartphones and televisions, along with tablets, utilize anisotropic conductive adhesives (ACAs) for their construction. The adhesive uses a unique conductivity design, which enables its application on sensitive circuit board components like LCD connections and antenna structures for RFIDs and portable PCB devices.

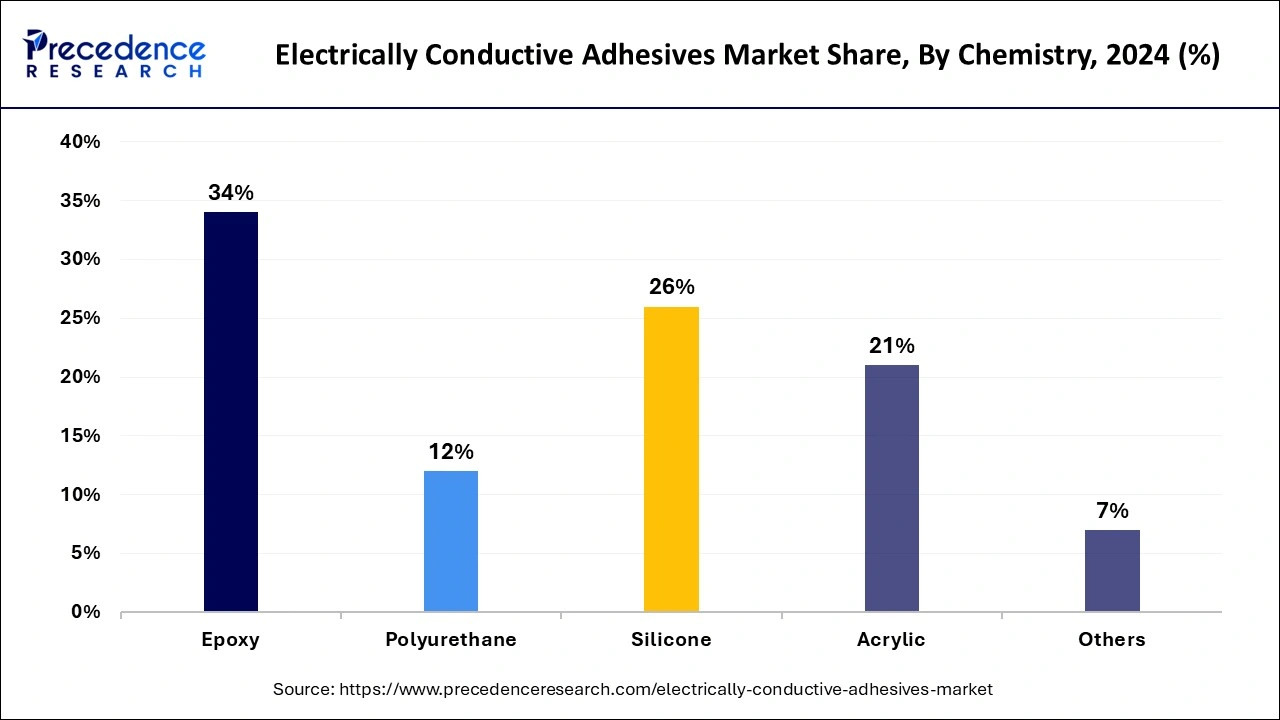

The epoxy segment has dominated the global electrically conductive adhesives market in 2024. Electrically conductive adhesives based on epoxy are common in applications such as touch panels, coating, RFID chip bonding, LED mounting, and additional uses. Property bonds require epoxy because some components do not tolerate heat exposure for soldering. Electrically conductive epoxy polymers work well as electrically conductive adhesive materials within operations that face extensive mechanical and thermal cracking issues. When electrically conductive epoxy polymers replace polyurethane, silicone, and other electrically conductive resins as solder alternatives, they provide cheaper costs while offering enhanced performance and speedier manufacturing processes. Epoxy polymers face growing market demand because of these identified factors throughout the upcoming forecast period.

The silicone segment is projected to witness the fastest growth during the forecast period. Electrically conductive silicone adhesives find their main applications in supporting RFI/EMI shielding and antistatic systems. Electrically conductive silicone adhesives exist because they fulfill requirements for superior conductivity and high flexibility at the same time. Silicone adhesives with conductive properties find their primary purpose in automotive applications through their function as connecting elements between ADAS cameras and radars as well as LiDARs. Electrically conductive silicone adhesives serve applications across multiple industries, including medical, telecom, and aerospace, which need electronic assembly solutions.

The silver filler segment generated a substantial electrically conductive adhesives market share in 2024. ECAs succeed because of their benefits in improving adhesion while enhancing moisture resistance and reducing shrinkage. The segment growth will experience positive momentum because high-performance conductive adhesive manufacturers are adopting the material from its wide array of available sizes and shapes. ECAs mainly use silver fillers because they demonstrate outstanding electric conductivity, high mechanical and thermal stability, and the ability to work with various substrates. These additives are widely utilized across consumer electronics devices as well as automotive systems, aerospace technology, and medical equipment devices. Silver-filled conductive adhesives have become popular for tiny devices such as smartphones as well as tablets, and wearables because they support dependable electrical connections inside small electronic products. The market demand for silver-filled ECAs increased because electric vehicles became more popular while the need for renewable energy grew at the same time.

The automotive segment noted the largest market share in 2024. Electrically conductive adhesives sustain wide application within the automotive industry. They enable functions in anti-lock braking systems, engine control units, and transmission control units. Electrically conductive adhesives serve in consumer electronics products as they create flexible electrical paths in multiple electronic products. The automotive industry will experience increased demand for electrically conductive adhesives because of its requirement for complex electronic components that need protection from electromagnetic radiation. The increasing application of these materials as interconnection components between ADAS cameras, radars, and LiDARs in cars will boost their market demand in the future. Electrically conductive adhesives serve as connecting interconnects for advanced driver assistance system (ADAS) cameras together with radars using light detection and ranging (LiDARs) in the automotive sector.

By Type

By Chemistry

By Filler Material

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

July 2024