January 2025

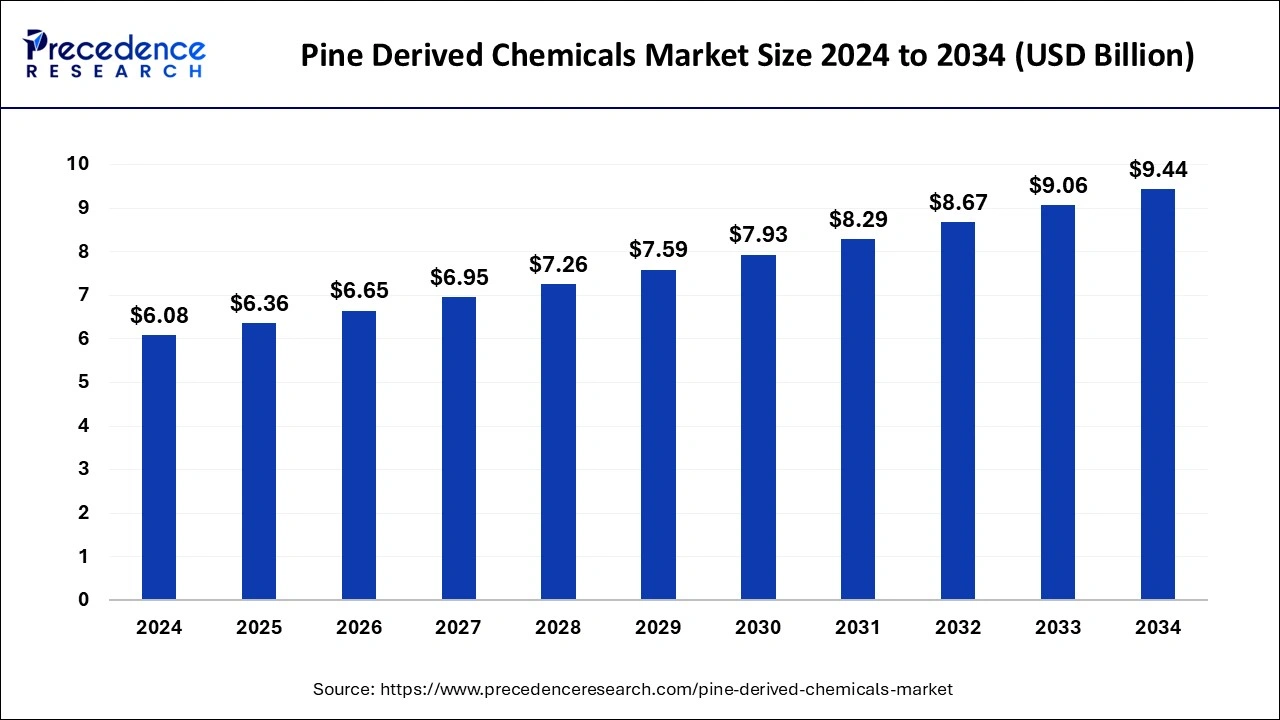

The global pine derived chemicals market size is calculated at USD 6.36 billion in 2025 and is forecasted to reach around USD 9.44 billion by 2034, accelerating at a CAGR of 4.50% from 2025 to 2034. The Asia Pacific pine derived chemicals market size surpassed USD 2.93 billion in 2025 and is expanding at a CAGR of 4.62% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global pine derived chemicals market size was estimated at USD 6.08 billion in 2024 and is predicted to increase from USD 6.36 billion in 2025 to approximately USD 9.44 billion by 2034, expanding at a CAGR of 4.50% from 2025 to 2034. Eco-friendly and sustainable chemical substitutes for petroleum-based ones are in greater demand from both consumers and businesses.

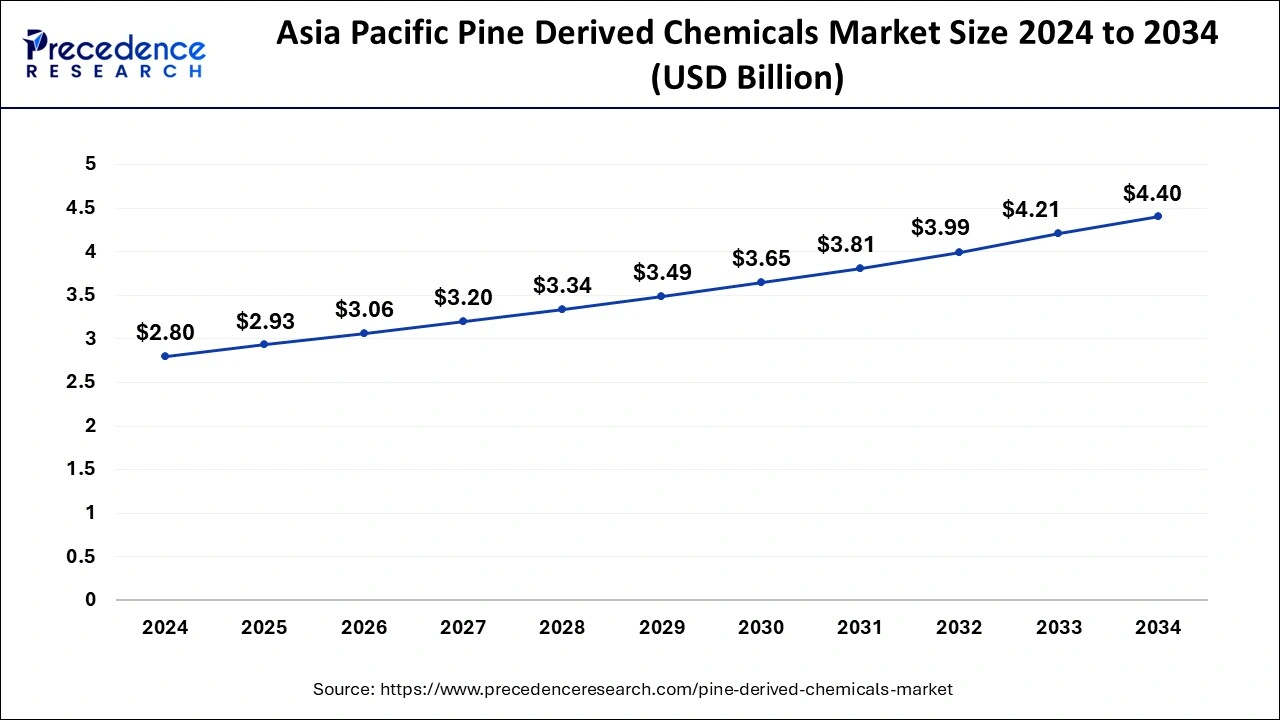

The Asia Pacific pine derived chemicals market size was exhibited at USD 2.80 billion in 2024 and is projected to be worth around USD 4.40 billion by 2034, poised to grow at a CAGR of 4.62% from 2025 to 2034.

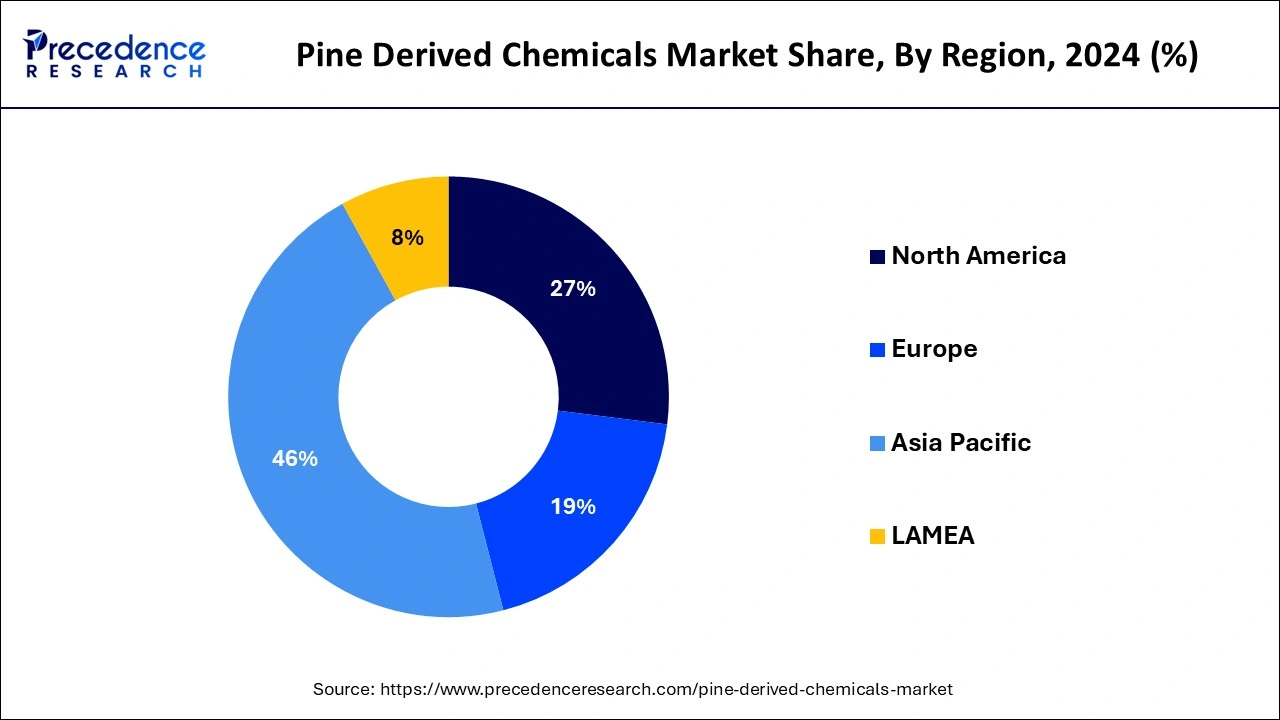

Asia Pacific held the largest share of the pine derived chemicals market in 2024. The Asia Pacific market for chemicals generated from pine is expanding significantly as a result of a number of factors, including the availability of raw materials, growing demand for bio-based products, and an increase in industrial applications. In the upcoming years, the Asia Pacific market for chemicals derived from pine is expected to rise significantly.

The market will probably advance because of the emphasis on sustainability, technical breakthroughs, and an increase in industrial applications.

In this changing environment, companies that prioritize innovation and strategic expansion should stand to gain the most. The availability of raw materials, industrial demand, and sustainability initiatives are driving the growth and vibrancy of the Asia Pacific market for chemicals produced from pine. Despite certain obstacles, things are looking up generally, and there are plenty of chances to improve.

North America is expected to host the fastest-growing pine derived chemicals market during the forecast period. Within the larger chemical industry, the North American market for compounds generated from pine is a small but expanding segment. These substances, which have a wide range of uses because of their adaptable qualities, are made from several sections of pine trees, including the bark, wood, and needles. Because of their binding qualities and tackiness, resins derived from pine trees are essential ingredients in a variety of adhesive formulations.

Pine compounds are utilized as food flavorings, air fresheners, and fragrances because of their pleasant scent. Pine-derived compounds are becoming more efficient and productive thanks to advancements in extraction and processing methods. Positive laws encouraging the usage of bio-based products are supporting market growth.

The pine derived chemicals market generated from pine is rising significantly due to a number of causes, including growing consumer demand for sustainable and eco-friendly products, developments in extraction and processing technology, and an increase in the number of applications in a variety of industries. Consumer interest in sustainable and biobased products is rising.

Chemicals generated from pine, which are renewable and environmentally friendly, are replacing petrochemicals in growing numbers. The quality and efficacy of these products are being improved by developments in the extraction, purification, and processing of pine compounds, increasing their competitiveness in the market. Chemicals generated from pine are utilized in many different industries, such as tires, adhesives, paints and coatings, tastes and perfumes, and pharmaceuticals.

Rising environmental laws, a move toward green chemistry, and an increase in industrial applications are all predicted to fuel market expansion. Future demand is also expected to be driven by innovations in biomass-based goods and growing uses in medicines and healthcare items.

In conclusion, the pine derived chemicals market generated from pine is expected to increase rapidly due to a variety of industrial uses, environmental initiatives, and technological breakthroughs. However, obstacles that must be overcome could include supply constraints and cost issues. The region's market is expanding because nations like China are concentrating on renewable resources and environmental restrictions.

| Report Coverage | Details |

| Market Size by 2034 | USD 9.44 Billion |

| Market Size in 2025 | USD 6.36 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 4.50% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Product, Process, End-use, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Market expansion in emerging economies

The products and services of the pine derived chemicals market are employed in a variety of sectors, including adhesives, paints, coatings, tastes, and scents. The main goods are tall oil, rosin, and turpentine. The expanding industrial base and rising need for these chemicals in emerging economies make them a profitable prospect. The demand for chemicals generated from pine in a variety of applications is rising as a result of emerging economies' rapid industrialization and economic expansion.

The pine derived chemicals market can grow if regulations promote environmentally friendly and sustainable chemicals. The pine-derived chemicals industry necessitates a deliberate, well-researched approach that takes into account local market realities, regulatory contexts, and consumer preferences in order to expand into emerging economies.

Market demand and awareness

Growing customer preferences and regulatory pressure to minimize carbon footprints are driving a trend in many industries toward the usage of bio-based and renewable resources. The pine derived chemicals market, due to their natural and renewable products, aligns nicely with this trend. The need for adhesives, coatings, and other products using chemicals produced from pine is greatly increased by the growing construction, automotive, and packaging industries.

The yield and quality of compounds obtained from pine have increased due to advancements in extraction and processing technology, giving them a competitive edge over synthetic products. Many industries are interested in the creation of novel and enhanced formulations that make use of compounds obtained from pine. These goods are more appealing because of improved qualities such as greater stability, gloss, and adherence.

Competitive landscape

A wide range of goods is available in the pine derived chemicals market, such as turpentine, rosin, tall oil, and derivatives such as fatty acids and terpene resins. This diversity serves a variety of industries, including paints, adhesives, perfumes, and food additives. Businesses spend money on R&D to improve the cost-effectiveness, sustainability, and quality of their products. Improved extraction techniques and bio-based substitutes for conventional petrochemicals are examples of innovations.

Sustainability programs and environmental standards are becoming more and more crucial to comply with. To reduce their influence on the environment, businesses are implementing eco-friendly procedures and investigating bio-refining methods. Businesses set themselves apart by innovation in products, improvements in quality, and tailoring to the demands of the pine derived chemicals market.

The turpentine segment dominated the global pine derived chemicals market in 2024. Pine tree turpentine is used as a solvent in a variety of industrial operations. It is important in sectors including paints and coatings, adhesives, and printing inks because of its capacity to dissolve oils, resins, and other organic compounds. Turpentine made from pine is used as a feedstock to make a variety of compounds. Pine oil is one of the most significant derivatives and is used in cleaning supplies, scents, and disinfectants. China, several European nations, and the United States (particularly the Southern states) are important producers of pine turpentine. Global supply is greatly impacted by the quality and availability of pine trees suited for turpentine extraction.

The tally oil fatty acid segment is expected to expand rapidly in the pine derived chemicals market in the upcoming years. The raw material used to make TOFA is crude tall oil, which is a byproduct of the kraft pulping process. TOFA is an essential component of dimer acids, which are produced and employed in the production of coatings, resins, and lubricants. Their cleaning characteristics make them useful in the manufacturing of soaps and surfactants. Because of its adhesive qualities, TOFA is used in the formulation of adhesives and sealants. Technological developments, environmental regulations, and industrial growth all have an impact on the need for compounds obtained from pine, especially tall oil fatty acids. The market for renewable and bio-based chemicals like TOFA is anticipated to expand as sustainability gains more traction.

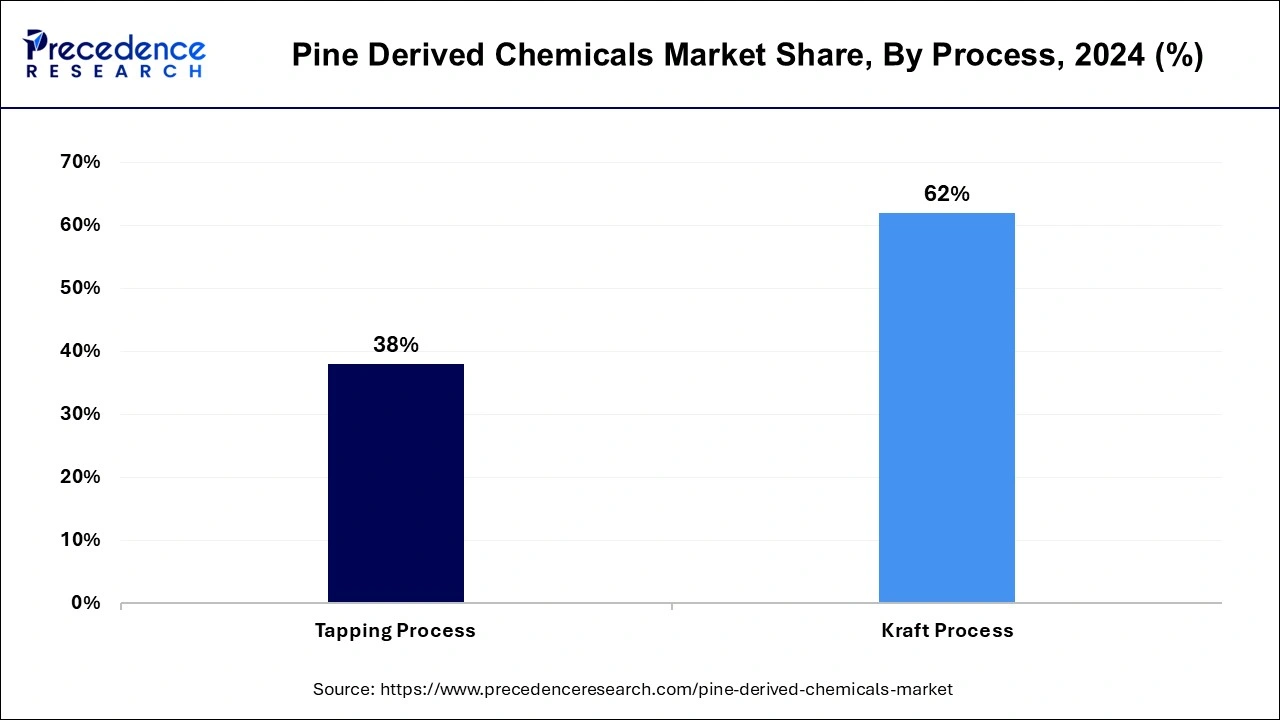

The kraft segment held a significant share of the pine derived chemicals market in 2024. The kraft method is more well-known for its use in the pulp and paper sector than in the market for chemicals generated from pine. However, interest in using pine wood and its byproducts for new processes, including variations on the kraft process, to produce different compounds has grown in recent years. Wood has been turned into pulp for papermaking using the Kraft process. In order to help break down the lignin and separate the cellulose fibers, wood chips are treated with a mixture of sodium hydroxide (NaOH) and sodium sulfide (Na2S) at high temperatures and pressures. Beyond the conventional pulp and paper products, pine trees and their byproducts, such as wood and resin, can be utilized to create a variety of chemicals.

The tapping segment is expected to grow at the fastest rate in the pine derived chemicals market during the forecast period. Pine trees are prized for their resin, which has a variety of chemicals that may be processed into a variety of goods used in the adhesive, flavor, and fragrance, among other industries. To get at the resin, a number of incisions or cuts must be made in the pine tree's bark. The production process can be carried out manually or with the aid of automated tools, contingent upon the producer's technological breakthroughs and production size.

The paints & coatings segment held the largest share of the pine derived chemicals market in 2024. Chemicals made from pine are sustainable and come from natural sources, which means they are a more environmentally responsible option than chemicals made from petroleum. Tall oil fatty acids (TOFA), rosin, and terpene derivatives are among the substances generated from pine that are utilized in paints and coatings. These materials are removed from pine trees during the pulping process, and they can be processed further to create a variety of chemical compounds that are appropriate for use in the coatings sector. Tall oil fatty acids (TOFA), rosin, and terpene derivatives are among the substances generated from pine that are utilized in paints and coatings. These materials are removed from pine trees during the pulping process, and they can be processed further to create a variety of chemical compounds that are appropriate for use in the coatings sector.

The pharmaceuticals segment is expected to grow rapidly in the pine derived chemicals market in the upcoming years. The market for medicines made from pine chemicals includes a range of goods that make use of organic substances that are taken from pine trees. Because of these substances' medicinal qualities and possible health advantages, they are utilized in medicines. This bark extract from the French maritime pine tree is patented.

It is utilized in nutritional supplements meant to enhance circulation, promote healthy skin, and lessen inflammation because of its well-known antioxidant qualities. Due to their antibacterial and anti-inflammatory qualities, these conventional compounds made from pine are utilized in pharmaceutical formulations and topical therapies. The market for pharmaceuticals made from pine is driven by both continuous research into the therapeutic effects of these chemicals and growing public awareness of and demand for natural health goods.

By Product

By Process

By End-use

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

January 2025

January 2025

May 2024