January 2025

The global specialty resins market size is estimated at USD 9.66 billion in 2025 and is predicted to reach around USD 16.17 billion by 2034, accelerating at a CAGR of 5.90% from 2025 to 2034. The Asia Pacific specialty resins market size is surpassed USD 5.99 billion in 2025 and is expanding at a CAGR of 5.92% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global specialty resins market size was estimated for USD 9.11 billion in 2024 and is anticipated to reach around USD 16.17 billion by 2034, growing at a CAGR of 5.90% from 2025 to 2034. Over the course of the projected period, rising demand from the building and construction industry is expected to substantially propel market expansion.

By improving the processes of formulation, production, and application, artificial intelligence is transforming the specialty resin industry. Al is being used by businesses like BASF, Huntsman, and Dow to enhance product performance, optimize resin compositions, and speed up research and development. Faster development cycles are made possible by Al-powered predictive modeling, and real-time production line monitoring is made possible by smart manufacturing systems, which guarantee constant quality and reduce waste. These Al-driven innovations meet the expanding needs of important industries like automotive, electronics, and coatings while increasing industry-wide efficiency and sustainability.

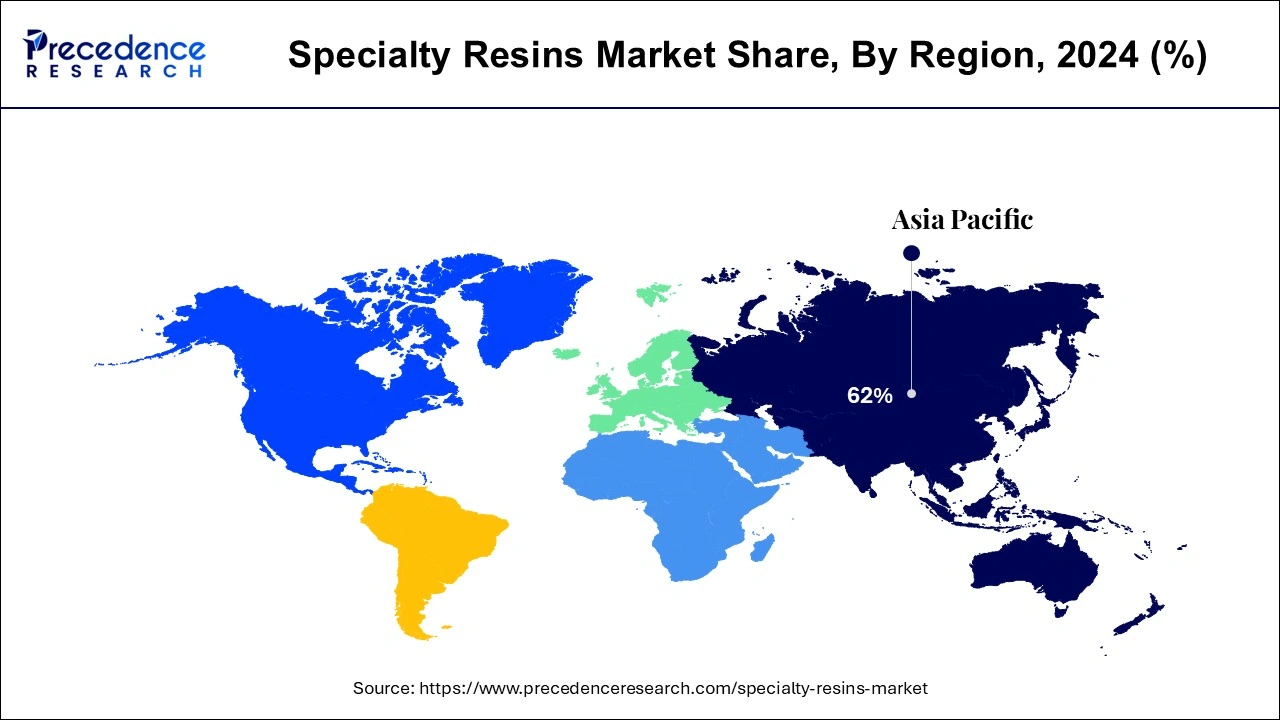

The Asia Pacific specialty resins market size was estimated at USD 5.65 billion in 2024 and is anticipated to be surpass around USD 10.03 billion by 2034, rising at a CAGR of 5.92% from 2025 to 2034.

The Asia Pacific dominated the global specialty resins market with the largest market share of 62% in 2024, in terms of volume and value, the region will likely dominate the specialty resins market globally during the forecast period. Asia Pacific's need for specialty resins is increasing due to rapid urbanization.

Significant customers of specialty resins in the Asia Pacific region include China, India, and Japan. Plastics, adhesives, paints, and coatings are also produced in large quantities in this area. Additionally, the Asia-Pacific automobile market has experienced tremendous growth over the past few years.

North America is estimated to grow significantly during the forecast period. Specialty resins are used extensively in the region's end-use sectors and several sizable resin makers. Innovative specialized resin products are now easily accessible due to the presence of major manufacturers in the U.S., such as Dow Chemicals, BASF, DuPont, and others. Resin firms have been forced to create low-emission specialized products due to strict environmental restrictions pertaining to volatile organic compound emissions in the paints and coatings sector. The position of North America has been further reinforced by this. Because end-use industries like construction and automotive are more developed, the area also has a well-structured supply chain. Epoxy and polyamide resins, which are employed in the production of electrical components in Asia, are the two principal types of specialty resins imported into North America.

Specialty resins are also known as commodity resins. Specialty resins are inexpensive plastics that may produce in large quantities. The most common specialty resin is epoxy resin, utilized as a composite material's matrix, adhesive, sealer, and coating binder. These resins can withstand heat and chemicals with ease. The production of specialized resins has grown in popularity over the last few years, witnessing a significant transformation in the global polymers industry. Creating specialized resins is one of the new market segments revolutionizing the world resin market.

Specialty resins have expanded significantly due to consumers' growing attention to product quality and personalization. The need for specialized resins is rising owing to rising demand for flooring, electronics, home appliances, packaging, and sports. Product improvements and new features are also increasing the development of the industry. A comprehensive analysis of the market for the expected term is provided in the report on the global specialty resins market.

| Report Coverage | Details |

| Market Size in 2025 | USD 8.1 Billion |

| Market Size by 2034 | USD 14.57 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 6.05% |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Largest Market | Asia Pacific |

| Segments Covered | Type, Function, Application, and Region |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, Middle East & Africa |

The market will likely increase significantly over the forecast period due to rising demand from the building and construction industries. The rising demand for specialty resins is related to rising construction investment for residential development, especially in North America and Western Europe. Specialty resins are resins that have distinct characteristics and are employed in a wide range of applications. Because they have more sophisticated properties, including chemical resistance, water resistance, and resistance to extreme temperatures, special resins cost more than standard resins.

Specialty resins play a significant role in the manufacture of various paints and coatings, which are then applied to multiple products for usage in industries like building and construction, marine, automotive, electrical & electronics, furniture, and home.

Specialty resins are a preferred material for usage in the building and construction sector due to their versatile features, which include excellent thermal resistance, strong chemical resistance, high hardness, and high UV resistance. The future looks promising for the global building sector, and specialty resin demand is increasing as a result. One of the industries in the Asia Pacific region that is proliferating is building and construction. Specialized resins must be used in adhesives, sealants, and coatings (protective, decorative, and architectural coatings) to achieve the quality standards of the building & construction business in Asia Pacific.

Specialty resins have excellent resistance to chemicals and temperature. Resins are likely to be widely used in the construction of infrastructure projects and residential and non-residential buildings in the future. Epoxy resin is used extensively in the aerospace industry, and the improvements in the product and new features will significantly expand the market in the following years.

Food and beverage production is expanding quickly, which will drive market expansion.

The middle-class population's salaries are rising quickly, altering consumer buying habits. In addition, the growing number of working women around the world benefits the food and beverage industry. Evolving lifestyles and fast-paced work environments are surging the demand for packaged food. Food makers want substantial, long-lasting food containers to safeguard products during storage and distribution.

The major players are also creating appealing resins to manufacture flexible packaging to meet the global need for healthy and nourishing products. Customers, particularly millennials, are stimulating demand for food and beverages by buying food with various flavors, which has inspired producers to innovate. This aspect will likely increase demand for specialized resins used in food and beverage packaging across the board.

The electronics segment will dominate the global specialty resins market.

Global demand for electronic devices has increased over the past few years. Due to convenience and a need for more modern technology, people are drawn to smarter, sleeker, and more sophisticated electronic gadgets. The demand for electronic devices is driven by shifting consumer lifestyles, ongoing developments, and the introduction of new items into the market. Numerous flexible polymers are needed by manufacturers for electrical equipment to be produced and function properly. Printed circuit boards (PCBs) and liquid crystal displays (LCDs) are crucial components in many applications, including homes, office buildings, aerospace, and automotive industries.

The creation of integrated circuits and other materials requires the use of specialty electronic resins. The devices' continually evolving designs make the electronics industry's specialty resins market unstable. Electronic manufacturers are looking for vendors who can supply their need for specialty resins as it is constantly changing. Increased investments in additive developments boost the market for this end-user as electronic gadgets become more complicated.

In the chemical commodities sector, the cost of raw materials has been rising. Due to this, the cost of specialized resins has also increased. Bisphenol A (BPA) and bisphenol F are the most often utilized bases for epoxy specialty resins (BPF). Under challenging applications, epoxy resins with high functionality are frequently needed to enhance product performance. For applications in coating, electronic and electric laminating, and composite construction, specialty resins are created especially for those uses.

Essential raw ingredients used in producing specialized resins made from unsaturated polyester include styrene, maleic anhydride, and phthalic anhydride. There has been a significant rise in the cost of these materials. During the projection period, fluctuating specialty resin feedstock prices are anticipated to restrain market growth.

Over the past few years, the water and wastewater treatment business has seen rapid growth worldwide. Approximately 40% of the treated water does not meet the requirements, and only 60% of the industrial wastewater is treated. Sewage treatment is a severe problem because urban water treatment facilities can treat only 37% of the sewage.

Ion exchange resins are crucial for the purification of water. These are typically produced using acrylic acid and the crosslinking ingredient divinyl benzene (DVB). Ion exchange resins are created by some firms using methacrylic acid or its byproducts. They are frequently utilized in demineralization facilities to de-alkalize water.

The epoxy segment contributed the highest market share of 36% in 2024. Epoxy resins, unsaturated polyester resins (EPS), vinyl, and polyamide are the four primary categories of specialty resins. Epoxies, often known as epoxy, are thermoset polymers composed of several three-membered rings. Epoxy, used as an adhesive, sealer, bond coat, and matrix for composite materials, is the most popular type of specialty resin. It is utilized in pipelines and tanks, as well as in the maritime and construction industries.

Printed circuit boards, rigid foams, coatings, automotive components, construction materials, metal foil laminates, and fiber-reinforced composites are just a few of the modern industrial uses for vinyl specialty resins. High-density, opaque polymers with exceptional strength and heat resistance belong to the family of thermoplastic polymers known as polyamides. Protection, insulation, and other features are just a few of the specific resin properties.

The protection function segment dominated the market in 2024, which dominated the industry. This report emphasizes insulation, protection, and other uses of specialty resin. The protection function market will likely have the most market share during the anticipated period.

Applications including building & construction, water treatment, marine, electrical & electronics, automotive, aerospace, and others are driving the market's rising demand. The low-density polymer individual cells make up the specialized resin's cells, which are not cross-linked and have a high strength-to-weight ratio, making them the ideal substance for a protective function.

The building and construction segment has held a major market share of 39% in 2024, which led the market. Due to the exceptional resistance to cracks, stains, blistering, harsh temperatures, and chemicals, specialty resins are frequently used in residential and commercial buildings, the marine industry, the automotive industry, and wastewater treatment facilities, among other places. Their products have excellent strong anti-corrosion performance, adhesion, and low volatile organic compound concentration.

It is anticipated that increasing demand in the construction sector will propel market expansion throughout the projected period. Building and infrastructure construction, product manufacturing and supply, product disposal, repair, maintenance, and forestry are all included in the expansive construction field.

By Type

By Function

By Application

By Geography

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

January 2025

November 2024

November 2024

November 2024