May 2025

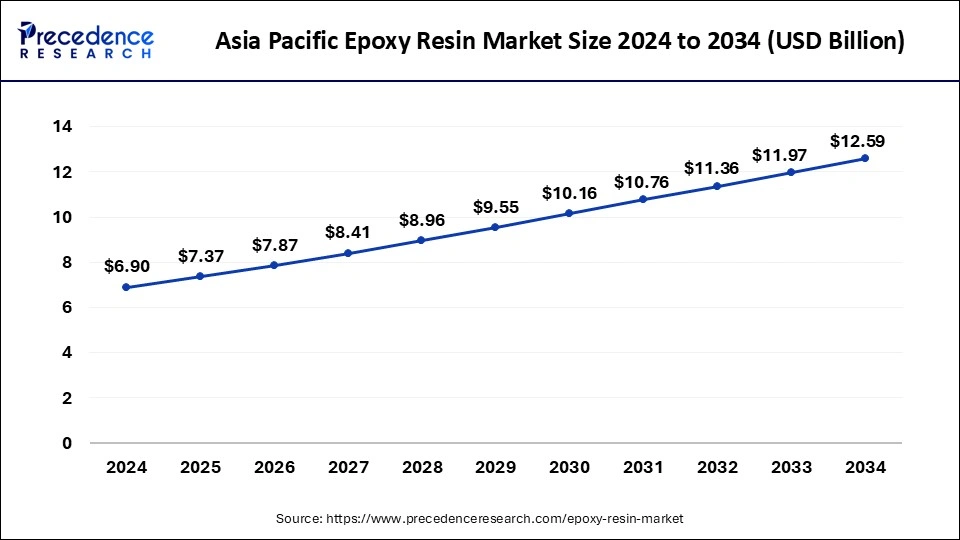

The global epoxy resin market size is calculated at USD 12.33 billion in 2025 and is forecasted to reach around USD 20.31 billion by 2034, accelerating at a CAGR of 5.71% from 2025 to 2034. The Asia Pacific market size surpassed USD 6.90 billion in 2024 and is expanding at a CAGR of 6.13% during the forecast period. The market sizing and forecasts are revenue-based (USD Million/Billion), with 2024 as the base year.

The global epoxy resin market size accounted for USD 11.58 billion in 2024 and is predicted to increase from USD 12.33 billion in 2025 to approximately USD 20.31 billion by 2034, expanding at a CAGR of 5.71% from 2025 to 2034.

The Asia Pacific epoxy resin market size was exhibited at USD 7.87 billion in 2025 and is projected to be worth around USD 12.59 billion by 2034, growing at a CAGR of 6.13% from 2025 to 2034.

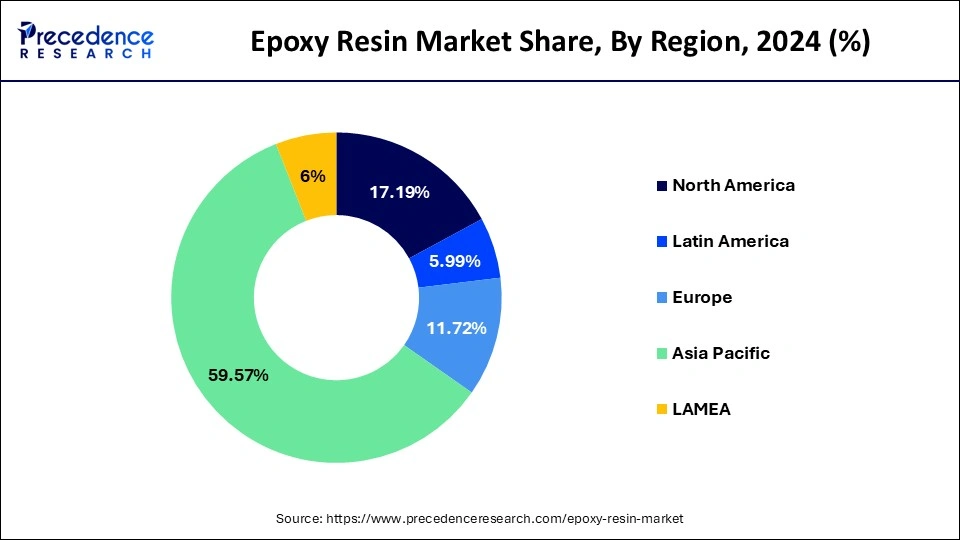

Attributed to the prevalence of large-scale manufacturers and the widespread access to raw materials, Asia Pacific accounted for the biggest volumes and market share in the global market in 2024. The Asia Pacific market is expected to be worth USD 6.90 billion in 2024. With favorable end-use industry growth in China, India, and South East Asian countries, the region is likely to lead this market during the forecast period. China is the world's biggest epoxies user.

The paint and coatings industry in the nation is well-established, and the majority of epoxy-based coatings are employed due to their excellent qualities. Furthermore, the rapidly growing composites, construction, and automotive sectors are growing significantly for long-lasting epoxies. India is likely to undergo rapid improvement in the foreseeable future as a result of expanding industrialization. Furthermore, countries like as South Korea and Japan hold a substantial portion of the regional market due to a very well epoxy supply chains and manufacturers.

In Europe, automobile, renewable power, and composites are driving the growth of higher and lower cured epoxy resins. Automotive part innovations, increased need for green chemicals in construction operations, and a booming green economy are just a few of the factors boosting epoxies demand in the area.

North America's increased digitization is driving higher demand for electrical and electronic products. To reduce costs and improve performance, these systems use long-lasting and trustworthy epoxy-based components. Furthermore, growing governmental and non-governmental infrastructure direct investment provides significant opportunities for market development. The good growth of the food and beverage sector is setting the stage for solutions such as metals container coatings.

China has the world's largest electronics manufacturing base and competes fiercely with established upstream producers such as South Korea, Singapore, and Taiwan. Electronic devices such as smartphones, OLED TVs, tablets, among others, have seen the most demand rise in the consumer electronics area of the industry. With rising middle-class disposable incomes, demand for electronic devices is expected to rise gradually in the future, propelling the industry under consideration. In India, the government is pushing for massive residential constructions in the next years. India has a USD 1400 billion infrastructure investment budget, with 24 percent going toward renewable energy, 19 percent going toward roads and highways, 16% going toward urban infrastructure, and 13 percent going toward railroads. Till June 2021, 2,734 of the total 5,956 Smart Cities Mission projects have been completed. As a result, expansion in the residential category is expected to boost the Asia-Pacific epoxy resins market.

Epoxy resin is the thermosetting polymer created by the copolymerizing the epoxide with another molecule which has two hydroxyl groups. It's mostly employed in non-reinforced applications such paints and varnishes, adhesives, and composites. Lightweight composite materials are now being used by car makers to address the requirement for improved design freedom, flexibility, high strength, and decreased vehicle weight. Epoxy resins have grown in popularity across end-use sectors ranging as of coating to the composites due to their superior physical, chemical, and mechanical qualities. These resins have an excellent adhesion to the wide range of the materials, making them certain excellent choice for their production of adhesives and sealants.

Special epoxies have it with higher heat resistance and endurance which plays an important role in the high-end application like wind turbines and composites manufacture. Leading firms are growing tremendously throughout the Middle East and Africa, where the regional epoxy marketplaces are the best performing. Sika AG, for example, finished the epoxy factory in Qatar and plans to start operations in April 2021. The company wants to capitalize on expected sales for epoxy-based adhesives and flooring in Qatari construction and infrastructure developments with this investment. Such market leaders' initiatives are projected to strengthen the supply chain and lay the groundwork for market development over the forecast period. The bulk of epoxies are produced by the core reactions of the Bisphenol-A with epichlorohydrin (ECH).

Furthermore, the very demand for epoxy resins for aerospace sectors has expanded rapidly for the construction of aircraft in which panels and helicopter, in which rotor blades. The lightweight and durability of epoxy resin, as well as its high heat with pressure tolerance, make it perfect for usage in a aircraft sector, which drives growth of the worldwide epoxy resin market. All of these reasons are projected to boost the further growth of this epoxy resin market in aerospace sector during the forecast period.

Epoxy resins, they are also used to shield solar panels from rapid temperature fluctuations. Epoxies are reasonably priced, simple to apply, and require minimal work. Because of their great creep resistance and tensile strength, epoxy thermosets are used to make the blades more robust. The use of epoxy resins mixed with various toughening agent on the wind turbine blades has yielded many favorable results considered in terms of making those blades corrosion resistant also fatigue-proof, resulting in increasing demand for epoxy resins from the wind energy sector.

However, changes in raw material costs affect the manufacturing price of epoxy resin, it might have an impact on market growth throughout the projection period.

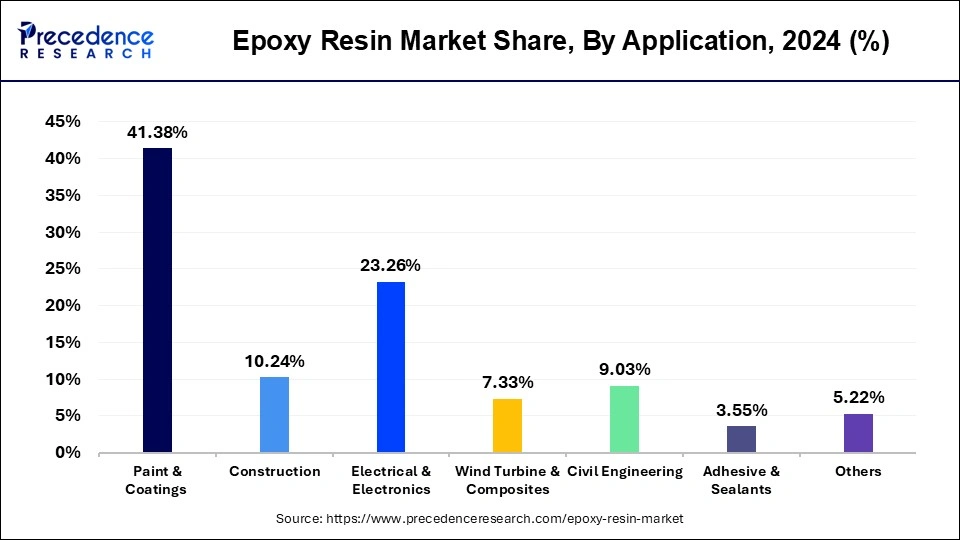

Epoxy resins aid in the creation of numerous coating qualities, including strength, durability, and chemical resistance. Their quick-drying, toughness, great adhesion, rapid curing, abrasion resistance, and excellent water resistance make it appropriate for protecting metals and other surfaces. The expanding construction sector is anticipated to help the paints and coatings business develop. In Europe, the German government announced a plan to build around 1.5 million housing units by the end of 2021. Similarly, rising building activity in countries such as Russia, France, and the United Kingdom is likely to propel the epoxy resins market forward.

The report estimates that 21.8 million light commercial vehicles, heavy buses, and trucks as well will be built globally in 2020. As a result, the increasing manufacture of lightweight and commercial vehicles are likely to increase the overall market for epoxy resins utilized in a automotive coatings sector. Epoxy coatings are used like the primers for corrosion protection in those of automotive, marine, and aerospace sectors. The use of epoxy coatings is likely to increase further as requirement from the electric vehicle (EV), marine, and aerospace sectors are on the rises. These factors are projected to have a substantial influence on demand for epoxy resins in the paints and coatings, impacting the positive growth of the epoxy resins market all the way through the forecast period.

Bio-based epoxies were developed to reduce the environmental impact of crude oil resins. Biomaterials which including lignin, vegetable oil, rosin, tannin, and so on replace a portion of the petrochemical products, ranging from 20% to 50%. These materials eliminate this need BPA, which is toxic and therefore must be dealt with caution. Bio-based resins have several uses, including paints, adhesive, composite, and many others.

Entropy Resins, Greenpoxy, and Resin Studies Bio Epoxy, for example, have commercially manufactured bio-based resins that include 20-50 percent bio-based components, according on the epoxy system. Because of the rising need for durability in epoxy end-use sectors, the opportunity for bio-based products can help to grow over the forecast period. Epoxy resins manufacturers are increasing output capacity to grow and capitalize on the revenue prospects in the aviation and construction industry. To fulfill the demanding demands of clients and consumers in the aviation and construction sectors, they are developing in paints, coatings, and adhesives. This is obvious since epoxy resins improve the durability of coating and paint compositions.

Furthermore, there is a rising need in the aviation and construction industry for paint and coating that can survive adverse weather and temperature conditions. Such needs are fueling the expansion of the epoxy resins market, moreover epoxy resins are accepted for their better mechanical strength and hardiness to harsh temperatures.

| Report Coverage | Details |

| Market Size by 2034 | USD 20.31 Billion |

| Market Size in 2025 | USD 12.33 Billion |

| Market Size in 2024 | USD 11.58 Billion |

| Growth Rate from 2025 to 2034 | CAGR of 5.71% |

| Largest Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Raw Material, Application, Technology, Sales Channel, End User and Geography |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

In 2024, the paint and coating application category led the market, accounting for much more than 41.38% of total revenue. Epoxy resin-based paints and coatings are widely utilized in residential housing constructions, maritime industries, automobiles, and sewerage systems due to their outstanding resistance to stains, fractures, temperature extremes, scorching, and solvents, among others. They have the great anti-corrosions performance and also low amount of Volatile Organic Compound (VOCs). inner and exterior surfaces of commercial, housing, institutional, and the industrial buildings are coated with epoxy resin-based paint and coating.

These adhesives and sealants not just to increase the aesthetic attractiveness of surfaces, and yet also preserve them from hot conditions and Ultraviolet rays, avoiding peeling, fading, and breaking. Emerging regions such as Asia Pacific, the Middle East, and Africa are seeing significant growth in quasi businesses such as IT, telecommunications, and retail, which is increasing consumption for coatings and adhesives. Likewise, continued industrialization, expanding government infrastructure expenditure, and rising Foreign Investments (FDI), notably in Asia Pacific, are anticipated to fuel the growth for epoxy resin-based paints and coatings throughout the projected period.

The DGBEA (Bisphenol A and ECH) segment led the market in 2024. DGBEA epoxy resins offer excellent versatility and performance across a wide range of applications. They exhibit high mechanical strength, chemical resistance, adhesion, and durability, making them ideal for various end-use industries such as construction, automotive, electronics, aerospace, and coatings. DGBEA epoxy resins can be formulated and customized to meet specific performance criteria and application requirements. Manufacturers can adjust the molecular weight, functionality, cross-linking density, and other parameters to tailor the properties of epoxy resin formulations for different end uses, enhancing their versatility and market appeal.

The solvent cut epoxy segment dominated the market in 2024. The addition of solvents to epoxy resin formulations improves their workability, allowing for better flow, wetting, and penetration into substrates. This facilitates smooth surface coverage and adhesion, resulting in high-quality finishes and strong bonds in various applications. Solvent-cut epoxy resins typically exhibit faster cure times compared to solvent-free formulations. The presence of solvents accelerates the curing process by promoting molecular mobility and facilitating cross-linking reactions between epoxy molecules and curing agents. This enables rapid production cycles and shorter lead times in manufacturing processes.

Global Epoxy Resin Market, By Technology, 2022-2024 (USD Million)

| By Technology | 2022 | 2023 | 2024 |

| Solvent Cut Epoxy | 3,028.0 | 3,237.1 | 3,457.7 |

| Liquid Epoxy | 2,469.7 | 2,637.6 | 2,814.5 |

| Waterborne Epoxy | 2,150.7 | 2,287.7 | 2,431.4 |

| Others | 2,530.6 | 2,697.7 | 2,873.4 |

The direct company sale segment held the dominating share of the market in 2024. Direct sales enable epoxy resin manufacturers to offer customized solutions tailored to the specific requirements of customers. By engaging directly with customers, companies can better understand their needs, preferences, and project specifications, allowing them to provide tailored epoxy resin formulations, technical support, and value-added services. Direct company sales ensure that customers receive epoxy resin products directly from the manufacturer, minimizing the risk of product tampering, contamination, or quality issues associated with intermediaries or third-party distributors. This direct supply chain ensures product authenticity, quality assurance, and adherence to industry standards and specifications.

Global Epoxy Resin Market, By Sales Channel, 2022-2024 (USD Million)

| By Sales Channel | 2022 | 2023 | 2024 |

| Direct Company Sale | 3,295.4 | 3,508.9 | 3,733.1 |

| Direct Import | 1,520.2 | 1,623.5 | 1,732.5 |

| Distributors & Traders | 3,010.4 | 3,221.4 | 3,444.4 |

| Retailers | 2,353.0 | 2,506.1 | 2,667.1 |

The consumer goods segment held the largest share of the market in 2024. Epoxy resins are widely utilized in the manufacture of adhesives and sealants for bonding and sealing a wide range of consumer goods, including electronics, appliances, automotive parts, and construction materials. Their strong bonding strength, moisture resistance, and temperature stability make them ideal for assembly and repair applications. Epoxy resins are essential components in the production of composite materials used in consumer goods such as aerospace components, sporting equipment, automotive parts, and recreational products.

They are combined with reinforcing fibers or fillers to create lightweight, high-strength composites that offer superior mechanical properties and design flexibility.

Evolving Epoxy Resin Market of the United States

The United States epoxy resin market is witnessing a spur demand, fueled by a convergence of factors that span multiple sectors. The construction sector is a prominent factor in the risen demand for epoxy resins in the United States. Epoxy resins are widely used in construction materials, including coatings, adhesives, and sealants. Aerospace and defense companies of the United States need high-performance materials, including adhesives, coatings, and aircraft ingredients. These industries make significant utilization of epoxy resins, which are well-known for their mechanical strength and lightweight nature.

By Raw Material

By Application

By Technology

By Sales Channel

By End User

By Region

For inquiries regarding discounts, bulk purchases, or customization requests, please contact us at sales@precedenceresearch.com

No cookie-cutter, only authentic analysis – take the 1st step to become a Precedence Research client

May 2025

January 2025

May 2025

February 2025